Introduction to PP Injection Molding for Durable Components

PP injection molded components are at the core of our manufacturing expertise, renowned for their exceptional durability and performance in challenging environments. Polypropylene (PP) is a versatile thermoplastic that, when shaped through our precision PP injection molding processes, creates components with outstanding mechanical properties. We specialize in producing PP injection molded parts that excel in two critical areas: impact resistance and moisture resistance. These qualities make them ideal for applications where parts must withstand physical stress, exposure to liquids, or humid conditions. Our team leverages advanced PP injection molding techniques to enhance these natural properties of PP, ensuring each component meets the highest standards of reliability. Whether used in industrial machinery, outdoor equipment, or consumer products, our PP injection molded components deliver consistent performance where it matters most.

The Impact Resistance of PP Injection Molded Components

The impact resistance of our PP injection molded components is a key advantage that sets them apart. PP inherently possesses good toughness, and through our optimized injection molding processes, we enhance this property further. We carefully control parameters such as melt temperature, cooling rate, and mold design to reduce internal stresses in the molded parts, minimizing the risk of cracking or breaking upon impact. For applications requiring extra durability, we use impact-modified PP grades that contain additives to improve toughness, even at low temperatures. This makes our PP injection molded components suitable for products like tool housings, automotive parts, and protective casings that may experience drops, collisions, or heavy loads. Our rigorous testing, including drop tests and impact strength measurements, ensures that every PP injection molded component can withstand the physical demands of its intended use, providing long-lasting reliability.

Moisture Resistance in PP Injection Molded Components

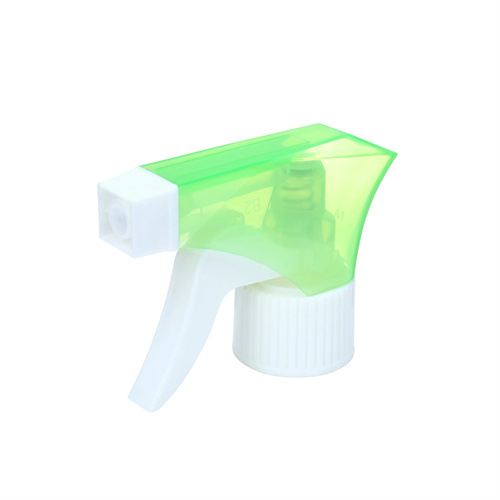

Moisture resistance is another standout feature of our PP injection molded components, making them perfect for wet or humid environments. PP is naturally hydrophobic, meaning it repels water and does not absorb moisture easily, and our PP injection molding processes enhance this characteristic. During molding, we ensure proper crystallization of the PP material, creating a dense structure that limits water penetration. This makes our PP injection molded components resistant to swelling, warping, or degradation when exposed to rain, humidity, or liquids. Unlike some other plastics, PP does not support microbial growth, adding to its suitability for applications where hygiene and moisture resistance are critical. From outdoor electrical enclosures and water pump parts to food storage containers, our PP injection molded components maintain their structural integrity and performance even after prolonged exposure to moisture, ensuring longevity in challenging conditions.

How We Enhance Properties in PP Injection Molding

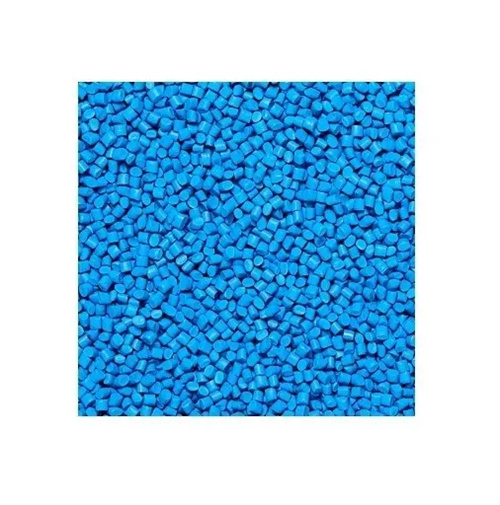

We employ specialized techniques in our PP injection molding processes to enhance the impact and moisture resistance of the components we produce. Material selection is key – we choose high-quality PP resins with the right molecular structure and additives to boost toughness and water resistance. For impact enhancement, we may incorporate rubber modifiers into the PP compound, which absorb energy during impacts and prevent crack propagation. In terms of moisture resistance, we optimize the molding cycle to ensure complete fusion of the PP molecules, creating a barrier against water ingress. Our mold designs also play a role, with features like tight tolerances and smooth surfaces that reduce moisture trapping points. Additionally, we use post-molding treatments such as annealing to relieve residual stresses, further improving the component’s ability to withstand impact and moisture. These targeted efforts in PP injection molding result in components with superior performance characteristics.

Industries Using PP Injection Molded Components for Resistance

Numerous industries rely on our PP injection molded components for their excellent impact and moisture resistance. The automotive industry uses them for under-hood parts, bumper components, and interior trim that must withstand vibrations, impacts, and occasional exposure to fluids. In the outdoor and recreational sector, our PP injection molded parts are found in lawn equipment, camping gear, and marine accessories, where resistance to weather and impacts is essential. The electrical industry trusts our components for junction boxes, cable management systems, and outdoor lighting housings, benefiting from their moisture resistance and durability. Food and beverage manufacturers use our PP injection molded containers and processing parts for their resistance to moisture, chemicals, and physical handling. Even in industrial settings, our PP injection molded components perform reliably in machinery, tooling, and storage solutions, proving their versatility across demanding sectors.

Quality Testing for Impact & Moisture Resistance in PP Injection Molding

We implement rigorous quality testing protocols to ensure the impact and moisture resistance of our PP injection molded components. For impact testing, we subject samples to controlled drop tests, Izod impact tests, and tensile impact tests to measure their ability to absorb energy without breaking. These tests are conducted at different temperatures to simulate various environmental conditions. For moisture resistance, we perform immersion tests where components are submerged in water for extended periods, followed by inspections for changes in dimensions, weight, or structural integrity. We also test for water vapor transmission rates to ensure minimal moisture penetration. Every batch of PP injection molded components undergoes these tests, with detailed records kept for traceability. By combining precise PP injection molding processes with stringent testing, we guarantee that our components consistently deliver the excellent impact and moisture resistance our clients depend on.