Industrial-Grade POM Formulations in Injection Molding

We specialize in industrial-grade POM injection molding using high-performance formulations engineered for the rigorous demands of mechanical components. Our selection of industrial acetal copolymers and reinforced POM grades delivers exceptional strength, wear resistance, and dimensional stability—critical properties for gears, bearings, and mechanical parts. These industrial-grade materials outperform standard plastics in high-stress applications, maintaining integrity under continuous load, friction, and environmental exposure. Our material experts collaborate with suppliers to source resins with consistent molecular weight distribution, ensuring uniform mechanical properties across production runs. We also offer custom compounding, incorporating additives like glass fibers for enhanced strength or PTFE for reduced friction, tailoring formulations to specific industrial requirements. This focus on industrial-grade formulations in POM injection molding ensures components meet the performance standards of heavy machinery, automation systems, and industrial equipment.

Precision Gear Manufacturing with POM Injection Molding

Our POM injection molding excels in producing precision industrial gears that deliver smooth operation, low noise, and long service life. We manufacture spur, helical, bevel, and custom gear designs using industrial-grade POM, leveraging the material’s natural low friction and excellent dimensional stability. Our molding processes maintain tight tolerances on tooth profiles, pitch diameters, and face widths—critical for gear meshing accuracy and torque transmission. We optimize mold designs with specialized gating that ensures uniform material flow to gear teeth, preventing defects that could cause premature wear or failure. Post-molding, we conduct detailed inspections using optical gear analyzers to verify tooth geometry and concentricity. Our POM gears outperform metal alternatives in many applications, offering corrosion resistance, lighter weight, and self-lubricating properties that reduce maintenance. This precision in gear manufacturing through POM injection molding results in reliable power transmission components for industrial machinery.

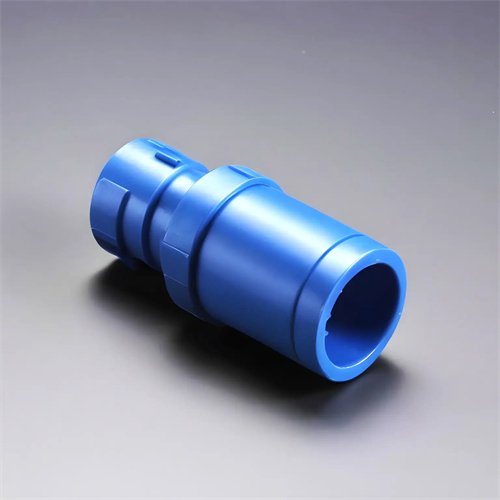

High-Performance Bearings & Bushings via POM Injection Molding

Industrial-grade POM injection molding produces high-performance bearings and bushings that excel in low-maintenance, high-wear applications. Our POM bearings leverage the material’s inherent low coefficient of friction and excellent wear resistance, eliminating the need for continuous lubrication in many industrial settings. We mold bearings and bushings with precise internal diameters, outer diameters, and wall thicknesses, ensuring proper clearance and fit in rotating assemblies. Our designs incorporate features like oil grooves, flanges, and alignment tabs that enhance functionality while maintaining manufacturability. We test POM bearing performance using simulated load conditions, measuring wear rates and friction coefficients to validate longevity. These components withstand harsh industrial environments, resisting chemicals, moisture, and temperature fluctuations that can degrade metal or lesser plastics. This focus on bearings and bushings in POM injection molding delivers cost-effective, low-maintenance solutions for conveyor systems, robotics, and rotating machinery.

Mechanical Part Durability in Industrial POM Injection Molding

Durability is a hallmark of our industrial-grade POM injection molding, ensuring mechanical parts withstand the rigors of continuous industrial operation. We engineer components to resist creep, fatigue, and impact damage—common failure modes in high-stress applications. Our molding processes eliminate internal stresses that could compromise structural integrity, using controlled cooling and optimized pressure profiles that enhance material density. We produce POM mechanical parts such as cam followers, linkages, and actuation components that maintain performance through millions of cycles. Our testing protocols include accelerated life testing, subjecting parts to extreme loads and cyclic stresses to validate long-term durability. We also verify resistance to industrial contaminants like oils, greases, and cleaning agents that could degrade lesser materials. This commitment to durability in industrial POM injection molding results in mechanical parts that reduce downtime and maintenance costs for industrial operations.

Dimensional Stability in Industrial POM Injection Molding

Dimensional stability is critical for industrial mechanical parts, and our POM injection molding processes ensure consistent dimensions across production and service life. Industrial-grade POM’s low moisture absorption and minimal shrinkage make it ideal for components requiring precise fits in assemblies, and our molding techniques enhance these properties. We maintain tight tolerances as low as ±0.0005 inches on critical features, using advanced mold flow analysis to predict and prevent dimensional variations. Our molds feature uniform cooling systems that promote even solidification, reducing warpage in complex mechanical parts. We subject finished components to thermal cycling and humidity testing, verifying that dimensions remain within specification under environmental changes. This stability ensures interchangeability between parts, simplifying maintenance and replacement in industrial settings. Dimensional consistency in industrial POM injection molding guarantees reliable assembly performance and component compatibility.

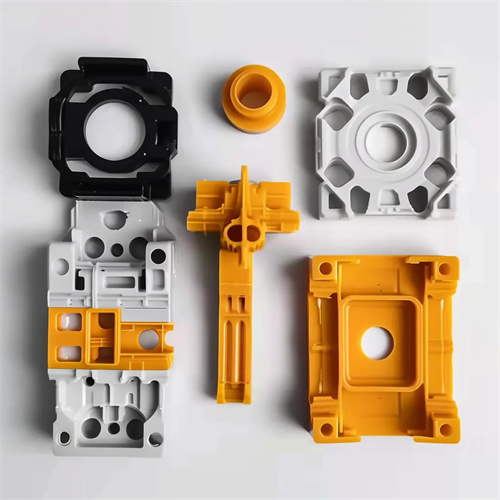

Custom Industrial Solutions Through POM Injection Molding

We provide custom industrial solutions through POM injection molding, tailoring designs and processes to meet the unique requirements of your mechanical components. Our engineering team collaborates with you to optimize part geometries for manufacturability and performance, offering design for manufacturability (DFM) insights that enhance functionality while reducing costs. We develop custom mold tooling for complex mechanical parts, incorporating features like undercuts, threads, and assembly aids that simplify integration into larger systems. For specialized applications, we modify POM formulations with additives that enhance specific properties—such as static dissipation for explosive environments or UV resistance for outdoor use. We support low-volume prototyping through to high-volume production, with scalable processes that maintain quality across all quantities. This custom approach to industrial POM injection molding delivers tailored solutions for gears, bearings, and mechanical parts that solve unique industrial challenges.