High-Temperature POM Formulations in Injection Molding

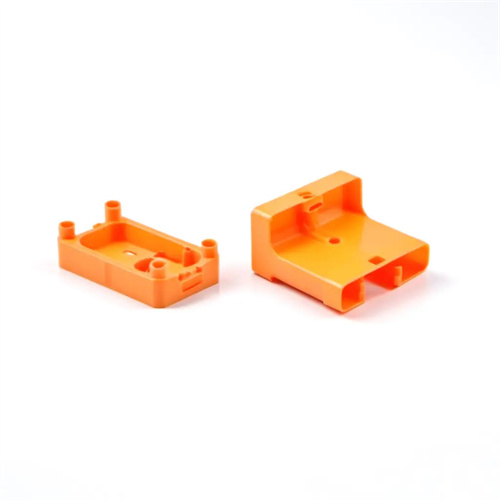

We specialize in high-temperature POM injection molding using advanced formulations engineered to maintain stability under thermal stress. Our selection of heat-resistant acetal copolymers and modified POM grades delivers reliable performance in elevated temperature environments up to 250°F (121°C) and beyond. These specialized POM materials retain their mechanical properties—including tensile strength, impact resistance, and dimensional stability—when exposed to continuous heat, unlike standard grades that may soften or degrade. Our material scientists collaborate with leading suppliers to source high-purity resins optimized for thermal endurance, ensuring consistent quality across production batches. We also offer custom compounding options, incorporating heat-stabilizing additives that enhance POM’s natural resistance to thermal oxidation. This focus on high-temperature formulations in POM injection molding ensures components perform reliably in the demanding thermal conditions of industrial and automotive applications.

Thermal Stability Engineering in POM Injection Molding

Thermal stability engineering is central to our high-temperature POM injection molding processes, ensuring parts maintain integrity under prolonged heat exposure. We’ve developed specialized molding parameters that optimize POM’s thermal performance, including precise melt temperature control and gradient cooling that minimizes internal stresses. Our molds feature advanced cooling channel designs that promote uniform solidification, reducing the risk of thermal warpage in complex geometries. We implement pre-drying protocols specifically calibrated for high-temperature POM, eliminating moisture that could compromise thermal stability. Post-molding, we subject critical components to controlled annealing processes that relieve residual stresses, enhancing long-term dimensional stability under thermal cycling. These engineering practices in high-temperature POM injection molding result in parts that resist creep, deformation, and performance degradation even when subjected to continuous or cyclic heat stress.

Performance Under Thermal Stress in POM Injection Molding

Our high-temperature POM injection molding produces components that deliver consistent performance under thermal stress, making them ideal for heat-intensive applications. We rigorously test parts under simulated operating conditions, exposing them to elevated temperatures for extended periods while measuring key performance metrics like friction coefficient, wear rate, and dimensional change. These tests validate that our high-temperature POM components maintain low-friction properties in hot environments, preventing seizing or increased wear in moving parts. We also evaluate thermal aging resistance, ensuring parts retain their mechanical strength and elasticity after prolonged heat exposure. Our high-temperature POM gears, bushings, and structural components maintain precise clearances and fit in assemblies despite thermal expansion, reducing the risk of jamming or failure. This focus on performance under thermal stress in POM injection molding ensures reliable operation in applications like engine compartments, industrial ovens, and heat-exchange systems.

Application-Specific High-Temperature POM Injection Molding

We develop application-specific high-temperature POM injection molding solutions tailored to the unique thermal demands of different industries. For automotive underhood applications, our high-temperature POM parts include fuel system components, turbocharger accessories, and engine bay linkages that withstand continuous heat from engines and exhaust systems. Industrial machinery benefits from our heat-resistant POM gears and bearings used in high-temperature processing equipment, where reliability under thermal stress is critical for uptime. Consumer appliances utilize our high-temperature POM components in oven mechanisms, dryer parts, and heating system controls that operate near heat sources. Our engineering team analyzes each application’s specific thermal profile—including temperature ranges, cycle frequency, and exposure duration—to select the optimal POM formulation and molding approach. This application-specific focus ensures our high-temperature POM injection molding solutions meet the exact thermal requirements of your product.

Precision Process Control in High-Temperature POM Injection Molding

Precision process control is essential for achieving consistent thermal performance in high-temperature POM injection molding, and our advanced systems ensure repeatable results across production runs. We use injection molding machines with closed-loop thermal control systems that maintain exact melt temperatures within ±1°F, critical for optimizing POM’s thermal properties. Our manufacturing execution system monitors and records key parameters like mold temperature, injection pressure, and cooling time, providing complete traceability for thermal performance validation. We implement statistical process control (SPC) for critical thermal-related dimensions, ensuring parts maintain precise tolerances even after thermal exposure. Our quality team conducts regular validation testing on production samples, verifying thermal stability and performance consistency. This precision process control in high-temperature POM injection molding guarantees that every part meets the same rigorous thermal performance standards, batch after batch.

Custom Solutions for High-Temperature POM Injection Molding

We offer custom high-temperature POM injection molding solutions designed to address your specific thermal challenges and performance requirements. Our engineering team collaborates with you to understand application temperature profiles, load conditions, and environmental factors, then develops tailored solutions that optimize thermal stability. We can modify POM formulations with specialized additives to enhance heat resistance, lubricity, or chemical compatibility in high-temperature environments. Our custom mold designs incorporate features like venting optimizations and cooling strategies that address the unique flow characteristics of high-temperature POM resins. We provide rapid prototyping services for high-temperature POM parts, allowing you to test thermal performance before full production. Whether you need small, complex components or large structural parts, our custom high-temperature POM injection molding solutions deliver the thermal stability and performance you need under stress.