Fuel Resistance Excellence in Automotive POM Injection Molding

Fuel resistance is a defining feature of our automotive POM injection molding components, making them ideal for critical underhood applications exposed to gasoline, diesel, and biofuels. We specialize in producing POM parts that maintain structural integrity and performance despite continuous contact with automotive fluids. Our selection of high-grade acetal copolymers offers superior resistance to hydrocarbon-based fuels, preventing swelling, cracking, or performance degradation over time. We’ve developed specialized molding parameters for automotive POM injection molding that enhance fuel resistance, including precise temperature control and optimized cooling that minimize material porosity. Our fuel system components—including fuel pump gears, valve housings, and connector parts—undergo rigorous immersion testing in various fuel formulations to validate long-term resistance. This focus on fuel resistance in automotive POM injection molding ensures reliable performance in even the most demanding fuel system applications.

High-Tolerance Manufacturing in Automotive POM Injection Molding

Automotive POM injection molding requires exceptional precision to meet the tight tolerances demanded by modern vehicle assemblies, and our processes deliver consistent dimensional accuracy in every component. We maintain tolerances as tight as ±0.0005 inches for critical automotive POM parts, ensuring proper fit and function in complex assemblies where even minor deviations can cause performance issues. Our high-precision molding machines feature advanced closed-loop control systems that monitor and adjust parameters in real time, compensating for variables that could affect dimensional stability. We design molds with specialized cooling channels that ensure uniform solidification of POM, minimizing warpage in intricate geometries common in automotive components. Post-production, our quality team uses coordinate measuring machines (CMMs) to verify dimensional accuracy across critical features. This commitment to high-tolerance automotive POM injection molding results in parts that integrate seamlessly into vehicle systems, reducing assembly issues and improving overall reliability.

Durability Under Extreme Conditions in Automotive POM Injection Molding

Automotive components must withstand extreme conditions, and our automotive POM injection molding produces parts engineered for durability in harsh environments. POM’s inherent resistance to wear, impact, and temperature fluctuations makes it ideal for automotive applications, and our molding processes enhance these natural properties. We produce POM components that operate reliably in underhood temperatures ranging from -40°F to 250°F (-40°C to 121°C), maintaining flexibility and strength across this broad range. Our automotive POM parts—including door lock mechanisms, window regulators, and transmission components—withstand vibration, mechanical stress, and exposure to road salts and cleaning chemicals. We subject components to accelerated aging tests, thermal cycling, and vibration testing to validate durability over extended service life. This focus on extreme condition performance in automotive POM injection molding ensures components deliver long-term reliability, reducing warranty claims and maintenance requirements for vehicle manufacturers.

Compliance with Automotive Standards in POM Injection Molding

We ensure all automotive POM injection molding components meet the strict standards and regulations governing the automotive industry, providing clients with fully compliant parts. Our POM materials meet ISO, SAE, and OEM-specific requirements for automotive applications, including flammability ratings, chemical resistance, and environmental performance. We maintain complete material traceability, documenting resin certifications, batch numbers, and test results for every production run. Our quality management system is certified to IATF 16949, the international standard for automotive quality management, ensuring rigorous process control and continuous improvement. We conduct testing to validate compliance with automotive standards, including emissions compatibility, material safety, and performance under regulatory test conditions. This focus on compliance in automotive POM injection molding gives manufacturers confidence that our components meet all industry requirements for safety, performance, and environmental responsibility.

Application-Specific Automotive POM Injection Molding Solutions

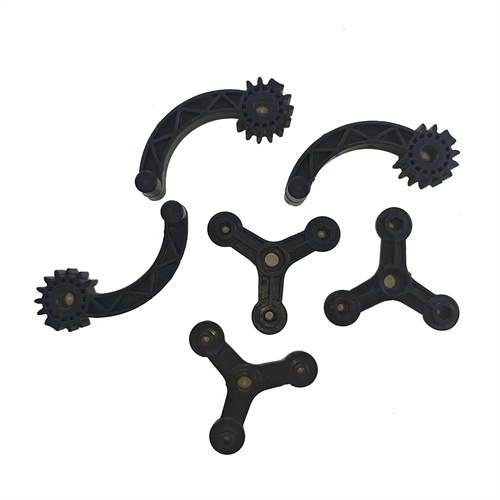

We develop application-specific automotive POM injection molding solutions tailored to the unique requirements of different vehicle systems. For powertrain applications, we produce high-strength POM gears and bushings that withstand high torque and temperature extremes. Our chassis components include POM bearing surfaces and linkage parts that deliver low-friction operation and long wear life. Interior systems benefit from our POM injection molding in components like seat adjuster mechanisms, door handles, and window switches that combine durability with smooth operation. Exterior applications utilize our weather-resistant POM parts, including mirror adjustment components and wiper system parts that withstand UV exposure and moisture. Our engineering team collaborates with clients to understand application-specific challenges, then develops automotive POM injection molding solutions optimized for performance, cost, and manufacturability in each vehicle system.

Cost-Effective Performance in Automotive POM Injection Molding

Our automotive POM injection molding delivers cost-effective performance by combining POM’s material advantages with efficient manufacturing processes that reduce overall vehicle system costs. POM offers an attractive alternative to metal in many automotive applications, providing comparable performance at lower weight and reduced production costs. Our high-volume molding capabilities for automotive POM parts achieve economies of scale that lower per-unit costs while maintaining quality. We optimize part designs for manufacturability, reducing material usage and cycle times in automotive POM injection molding without compromising performance. The long service life of our POM components also reduces lifecycle costs by minimizing replacement needs. Additionally, POM’s self-lubricating properties eliminate the need for additional lubrication in many applications, reducing assembly steps and maintenance requirements. This balance of performance and cost in automotive POM injection molding makes it an intelligent choice for budget-conscious manufacturers without sacrificing quality or reliability.