Precision Engineering for Automotive Plastic Injection Molded Parts

We specialize in producing precision plastic injection molded parts that meet the rigorous demands of the automotive industry, where performance, safety, and reliability are paramount. Automotive applications require parts with tight tolerances, consistent dimensional stability, and resistance to extreme temperatures, chemicals, and vibrations. Our engineering team works closely with automotive manufacturers to develop components such as sensor housings, interior trim pieces, underhood components, and electrical connectors that meet strict industry standards. We use high-performance engineering plastics like PBT, PA66, and PEEK that offer excellent mechanical properties and thermal resistance. Our advanced molding processes ensure that every automotive plastic injection molded part maintains precise tolerances as tight as ±0.001 inches, critical for proper fit and function in complex assemblies. We also implement rigorous testing protocols to validate performance under simulated driving conditions, ensuring our parts contribute to the overall safety and efficiency of modern vehicles.

Medical-Grade Quality in Precision Plastic Injection Molded Parts

The medical industry demands the highest level of precision and purity in plastic injection molded parts, and we deliver components that meet or exceed these stringent requirements. Our medical-grade plastic injection molded parts are used in a wide range of applications, including diagnostic equipment, surgical instruments, drug delivery systems, and patient monitoring devices. We operate in controlled manufacturing environments that adhere to ISO 13485 standards, ensuring cleanliness and traceability throughout production. Our materials include USP Class VI-certified plastics and biocompatible resins that meet FDA regulations for medical devices. We maintain exceptional precision in every part, with critical features held to tolerances that ensure proper functionality in life-saving equipment. Our quality control processes include 100% visual inspection, dimensional verification using CMMs, and material testing to confirm biocompatibility and sterility compatibility. By prioritizing precision and compliance, we produce medical plastic injection molded parts that healthcare professionals can trust.

High-Tech Solutions for Electronic Plastic Injection Molded Parts

The electronics industry relies on precision plastic injection molded parts to protect sensitive components, ensure proper functionality, and enable miniaturization trends. We produce a wide range of electronic components, including connector housings, circuit board enclosures, heat sinks, and display bezels, all engineered to meet the unique challenges of electronic applications. These parts require exceptional dimensional accuracy to ensure proper mating of components, as well as electrical insulation or conductivity properties depending on the application. We work with specialized materials like LCP (liquid crystal polymer) and PEEK that offer excellent flow characteristics for thin walls and tight tolerances, as well as high-temperature resistance for components near heat-generating electronics. Our molding processes minimize flash and burrs that could interfere with electronic functionality, and we offer secondary services like EMI shielding application when needed. By combining material expertise with precision manufacturing, we deliver electronic plastic injection molded parts that enable reliable performance in today’s advanced devices.

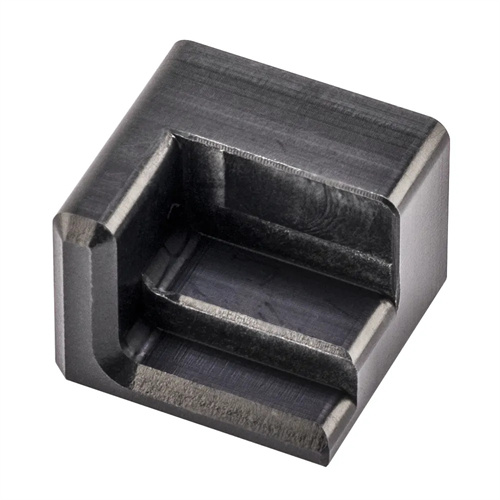

Advanced Molding Processes for Cross-Industry Plastic Injection Molded Parts

While automotive, medical, and electronics industries have distinct requirements, we leverage advanced molding processes that deliver precision plastic injection molded parts across all sectors. Our state-of-the-art facility features computer-controlled injection molding machines with closed-loop feedback systems that maintain precise control over temperature, pressure, and cycle times. We use advanced mold-making techniques, including CNC machining and EDM, to create molds with complex geometries and tight tolerances that translate to high-quality parts. For all industries, we implement mold flow analysis to optimize part design and prevent issues like warping or uneven filling. Our process validation protocols ensure consistent quality across production runs, whether producing 100 or 100,000 parts. We also offer value-added services such as assembly, testing, and packaging that streamline our clients’ supply chains. This cross-industry expertise allows us to bring best practices from each sector to every project, resulting in precision plastic injection molded parts that exceed expectations regardless of the application.

Material Expertise for Specialized Plastic Injection Molded Parts

Selecting the right material is critical for precision plastic injection molded parts in automotive, medical, and electronics applications, which is why our material scientists play a key role in every project. For automotive applications, we recommend materials based on factors like impact resistance, chemical compatibility with fuels and lubricants, and thermal stability under the hood. In medical applications, material selection focuses on biocompatibility, sterilization resistance, and clarity for visual components. For electronics, we prioritize dielectric strength, dimensional stability at varying temperatures, and flame retardancy. Our extensive material portfolio includes engineering resins, high-performance polymers, and specialty compounds that can be reinforced with fibers or filled with conductive additives. We work closely with clients to understand their application requirements, then recommend materials that balance performance, cost, and manufacturability. We also provide material certification and testing data to ensure compliance with industry-specific regulations, giving our clients confidence in their precision plastic injection molded parts.

Custom Precision Solutions Across Automotive, Medical & Electronics

We understand that each industry has unique challenges, which is why we offer custom precision plastic injection molded parts tailored to the specific needs of automotive, medical, and electronics clients. Our engineering team collaborates with you from the design phase, providing DFM (design for manufacturability) feedback that optimizes your part for precision molding while maintaining functionality. For automotive clients, we focus on durability and cost-effectiveness for high-volume production. For medical customers, we emphasize compliance and biocompatibility. For electronics manufacturers, we prioritize miniaturization and material performance. We offer rapid prototyping services to validate designs before full production, using the same precision processes as our production runs to ensure design intent is maintained. Our flexible manufacturing capabilities allow us to handle both low-volume specialty parts and high-volume production runs with equal precision. By combining industry-specific expertise with custom solutions, we deliver precision plastic injection molded parts that drive innovation across automotive, medical, and electronics sectors.