PET Injection Molding for Medical-Grade Materials: FDA Compliance Foundations

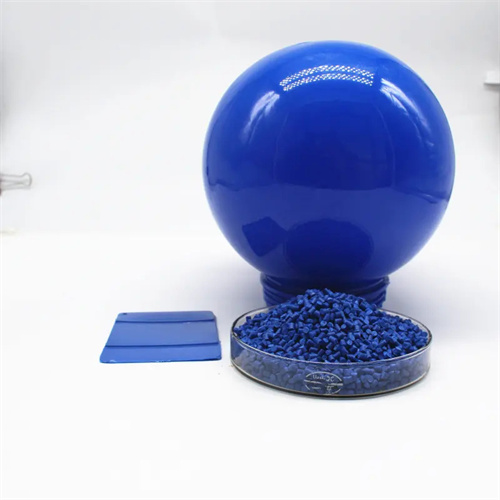

Our medical-grade PET injection molding services start with selecting FDA-compliant materials that meet the strictest standards for healthcare applications. We use virgin medical-grade PET resins certified to comply with FDA regulations, including 21 CFR 177.1630 for plastic materials in contact with food and pharmaceuticals. These resins are free from harmful additives, heavy metals, and leachable substances, ensuring biocompatibility for patient safety. Our material scientists conduct rigorous testing on each resin batch, verifying purity, molecular weight, and mechanical properties before production. During PET injection molding, we maintain dedicated production lines for medical components to prevent cross-contamination with non-medical materials. This commitment to material integrity forms the foundation of our FDA-compliant parts, whether producing surgical instrument handles, diagnostic device housings, or medication delivery components.

PET Injection Molding Sterilization Compatibility: Withstanding Medical Processes

Sterilizability is a critical feature of our medical-grade PET injection molding, as our parts must withstand common medical sterilization processes without degradation. PET’s inherent heat resistance makes it compatible with autoclaving (steam sterilization at 121–134°C), a widely used method in healthcare facilities. Our PET injection molding processes optimize material crystallinity to enhance thermal stability, ensuring parts maintain dimensional integrity after repeated autoclave cycles. We also validate compatibility with ethylene oxide (EtO) sterilization, a low-temperature method suitable for heat-sensitive components, by ensuring PET resins resist chemical interactions with EtO residuals. For radiation sterilization (gamma or electron beam), we use radiation-stabilized PET formulations that prevent chain scission and maintain mechanical strength. Each sterilization method undergoes validation testing, confirming that our PET injection molded parts retain functionality and safety after sterilization.

PET Injection Molding Quality Control for Medical Compliance: Rigorous Validation

Our medical-grade PET injection molding implements comprehensive quality control to ensure FDA compliance and consistent performance in clinical settings. We follow ISO 13485 standards for medical device manufacturing, with documented processes for every production stage—from material receipt to final inspection. In-line sensors monitor critical molding parameters (temperature, pressure, cycle time) in real time, with automated adjustments to prevent deviations. Post-production, we conduct 100% visual inspection for defects and use coordinate measuring machines (CMMs) to verify dimensional accuracy, ensuring parts meet tight tolerances for device assembly. Biocompatibility testing per ISO 10993 standards is mandatory, evaluating cytotoxicity, irritation, and sensitization risks. We also maintain full traceability, documenting resin batches, production dates, and inspection results for each part, facilitating FDA audits and recall management if needed. This rigorous control ensures our PET injection molded parts meet uncompromising medical quality standards.

PET Injection Molding for Critical Medical Components: Performance Under Pressure

Our medical-grade PET injection molding produces critical components that perform reliably in demanding healthcare environments. PET’s high tensile strength and impact resistance make it ideal for surgical tools, where durability during procedures is essential. We manufacture diagnostic device components with PET injection molding, leveraging the material’s dimensional stability to ensure precise fit with sensors and electronics. Medication delivery systems, such as inhaler housings and syringe components, benefit from PET’s chemical resistance, preventing interactions with pharmaceuticals. For wearable medical devices, our lightweight PET parts enhance patient comfort without sacrificing structural support. Each component undergoes functional testing, simulating clinical use cases to validate performance under pressure, vibration, and repeated handling—ensuring our PET injection molded parts support healthcare professionals and patients alike.

PET Injection Molding Design for Medical Applications: Customized Solutions

Our medical-grade PET injection molding offers customized design solutions tailored to specific medical device requirements while maintaining FDA compliance. We collaborate with device manufacturers to design parts with integrated features, such as ergonomic grips for surgical tools, snap-fit assemblies for easy disassembly, and fluid channels for medication delivery systems. Our design team uses 3D modeling to optimize part geometry for PET injection molding, ensuring uniform wall thickness to prevent warping and incorporating draft angles for easy mold release. For complex components, we implement insert molding to integrate metal or ceramic elements—such as threaded inserts for secure fastening—without compromising sterility. We also offer color customization using FDA-approved pigments, enabling color-coding for instrument identification or brand alignment. This design flexibility ensures our PET injection molded parts meet both functional and regulatory needs.

PET Injection Molding Regulatory Support for Medical Devices: Navigating Compliance

Beyond production, our medical-grade PET injection molding provides regulatory support to help clients navigate FDA requirements and market approval processes. We maintain detailed documentation for each production run, including material certificates, process validation reports, and test results—essential for 510(k) submissions or PMA applications. Our regulatory team stays updated on evolving FDA guidelines for plastic medical devices, advising clients on design changes or material selections that maintain compliance. We assist with risk management documentation, identifying potential failure modes in PET components and implementing mitigations. For international clients, we ensure compliance with additional standards like EU MDR and ISO 10993, facilitating global market access. This comprehensive regulatory support, combined with our technical expertise in PET injection molding, makes us a trusted partner for medical device innovation.