PET Injection Molding for Custom Packaging: Balancing Durability & Recyclability

Our custom PET plastic molding services specialize in creating packaging components that combine exceptional durability with high recyclability, meeting the dual demands of performance and sustainability. As experts in PET injection molding, we leverage polyethylene terephthalate’s inherent strength and clarity to produce packaging that protects products while remaining fully recyclable. PET’s high tensile strength and impact resistance make it ideal for rigid packaging components like bottle caps, container lids, and blister packs, which must withstand transportation, handling, and storage stresses. We optimize our PET injection molding processes to enhance these natural properties, ensuring parts maintain structural integrity throughout the product lifecycle. By focusing on both durability and recyclability, our custom PET packaging components support brands’ sustainability goals without compromising on protection or functionality.

PET Injection Molding Durability: Engineering Packaging for Product Protection

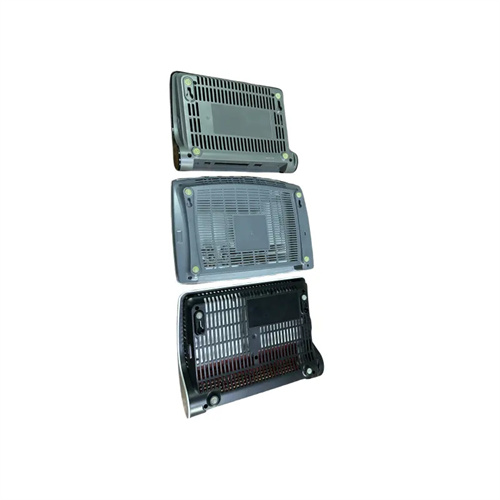

The durability of our custom PET packaging components is achieved through precision PET injection molding techniques that optimize material performance for product protection. We use high-quality PET resins with controlled molecular weight distribution, ensuring consistent strength and impact resistance across production runs. Our engineering team designs packaging with reinforced features, such as ribbed edges, thickened walls, and secure closure mechanisms, all enhanced through specialized injection molding parameters. During production, we control cooling rates to maximize crystallinity in critical areas, improving scratch resistance and reducing the risk of cracking or deformation. These durable PET components excel in protecting sensitive products—from food and beverages to cosmetics and electronics—resisting moisture, punctures, and crushing forces. Our PET injection molding ensures packaging maintains its protective properties even after repeated use, extending both product shelf life and packaging usability.

PET Injection Molding Recyclability: Closing the Loop in Packaging

Recyclability is a core feature of our custom PET plastic molding, as PET injection molding produces packaging components compatible with global recycling systems. PET is one of the most widely recycled plastics, with established collection, sorting, and reprocessing infrastructure that enables closed-loop recycling. We formulate our PET resins without non-recyclable additives or coatings, ensuring components can be easily processed into rPET (recycled PET) at the end of their lifecycle. Our PET injection molding processes use virgin and recycled PET blends, with up to 50% recycled content in applicable applications, reducing reliance on virgin plastic. We also design packaging with minimal material usage and simple geometries that facilitate efficient recycling, avoiding multi-material constructions that complicate separation. By prioritizing recyclability in PET injection molding, we help brands create packaging that supports circular economy goals and meets consumer demand for sustainable products.

PET Injection Molding Custom Design: Tailored Packaging Solutions

Our PET injection molding offers extensive customization to create packaging components tailored to specific product and brand needs. We collaborate with clients to design custom shapes, sizes, and features that enhance product visibility, usability, and brand recognition. For food packaging, this includes tamper-evident seals, portion-control designs, and microwave-safe components—all achievable through precision PET injection molding. Cosmetic and personal care packaging benefits from custom color matching, textured surfaces, and ergonomic grips that elevate brand aesthetics. We also integrate functional features like snap-fit closures, dispensing mechanisms, and barcode-ready surfaces directly into mold designs, eliminating secondary operations. Our design team uses 3D modeling to optimize each custom PET component for injection molding, ensuring manufacturability while achieving the desired durability and recyclability characteristics.

PET Injection Molding for Sustainable Branding: Eco-Friendly Packaging Solutions

Our custom PET plastic molding supports sustainable branding through PET injection molding solutions that align with environmental values. We help brands highlight their commitment to sustainability by producing packaging components with recycled content, clearly marked with resin identification codes (resin #1) to encourage proper recycling. Our PET injection molding creates lightweight packaging that reduces transportation emissions and material usage, further lowering environmental impact. For brands seeking eco-certifications, we provide documentation verifying recycled content percentages and compliance with standards like FDA food contact and EU 10/2011. We also offer custom messaging options, such as embossed recycling instructions, produced during PET injection molding to educate consumers on proper disposal. These sustainable branding elements, combined with durable performance, make our custom PET packaging a powerful tool for brands prioritizing environmental responsibility.

PET Injection Molding Quality & Consistency: Reliable Packaging Production

Consistent quality is essential in our custom PET plastic molding, as PET injection molding must deliver reliable performance for packaging applications at scale. We implement rigorous quality control throughout production, starting with material testing to verify PET resin purity and mechanical properties. In-line sensors monitor injection molding parameters in real time, adjusting pressure, temperature, and cycle times to maintain dimensional accuracy and structural integrity. Our quality team conducts visual inspections, dimensional measurements, and impact testing on sampled components, ensuring they meet specifications for fit, function, and durability. We also verify recyclability through compatibility testing with standard recycling processes. This commitment to quality ensures that whether producing 10,000 or 1,000,000 custom PET packaging components, every unit meets the same high standards for performance, sustainability, and brand representation.