PE Injection Molding: HDPE vs. LDPE for Targeted Performance

Our PE injection molding services specialize in both high-density (HDPE) and low-density (LDPE) polyethylene solutions, each tailored to deliver specific performance characteristics for diverse applications. HDPE, with its linear molecular structure and higher crystallinity, offers superior rigidity, tensile strength, and chemical resistance—ideal for structural components requiring dimensional stability. LDPE, characterized by its branched molecular structure, provides flexibility, impact resistance, and ductility, making it perfect for parts needing elasticity or squeeze functionality. Our expertise in PE injection molding allows us to recommend the optimal resin: HDPE for rigid containers, industrial parts, and load-bearing components; LDPE for flexible packaging, seals, and consumer products requiring bendability. By matching polyethylene density to application needs, our PE injection molding services ensure parts perform as intended while optimizing production efficiency.

PE Injection Molding for HDPE Applications: Strength & Durability Focus

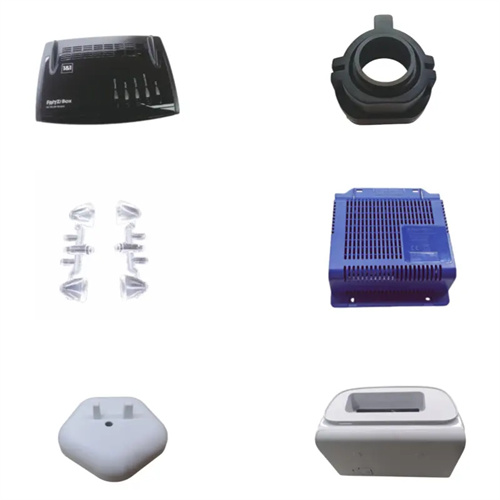

Our PE injection molding excels in producing high-quality HDPE parts that leverage the material’s inherent strength and durability for demanding applications. We optimize molding parameters to enhance HDPE’s natural advantages, including precise temperature control to ensure uniform crystallinity and pressure settings that maximize molecular density. This results in HDPE components with excellent impact resistance, even at low temperatures, and superior resistance to chemicals, moisture, and abrasion. Common HDPE applications include industrial containers, automotive fuel system components, and food storage vessels—all requiring the structural integrity our PE injection molding delivers. We also design HDPE parts with tight tolerances for applications like plumbing fittings and mechanical components, ensuring consistent performance across high-volume production runs. Our HDPE injection molding expertise ensures parts that combine strength, durability, and dimensional stability for long-lasting performance.

PE Injection Molding for LDPE Applications: Flexibility & Versatility

In LDPE applications, our PE injection molding processes highlight the material’s flexibility and versatility, creating parts that excel in dynamic, user-centric applications. We adjust molding parameters to preserve LDPE’s branched molecular structure, maintaining its elasticity while ensuring proper flow and fill during production. This results in LDPE components with excellent puncture resistance, stretchability, and low-temperature flexibility—critical for products like squeeze bottles, flexible lids, and toy components. Our PE injection molding for LDPE includes specialized techniques to produce thin-walled parts with consistent thickness, ideal for flexible packaging and protective covers. We also enhance LDPE’s natural tackiness for applications requiring sealing properties, such as gaskets and closures. Whether producing single-use items or reusable flexible parts, our LDPE injection molding ensures consistent flexibility and performance across every unit.

PE Injection Molding Process Optimization: Tailoring to Density Requirements

Our PE injection molding services include process optimization tailored to the specific requirements of HDPE and LDPE, ensuring optimal results for each density. For HDPE, we use higher melt temperatures and longer cooling cycles to promote proper crystallization, enhancing strength and dimensional stability. Our mold designs for HDPE incorporate features like thicker walls and reinforced ribs, supported by PE injection molding parameters that prevent warping during cooling. For LDPE, we utilize lower injection pressures and faster cycle times to maintain flexibility, with mold designs featuring smoother surfaces that enhance the material’s natural gloss and feel. We also adjust screw configurations in our injection molding machines to accommodate each resin’s unique flow properties—critical for achieving uniform part quality. This density-specific process optimization ensures our PE injection molding produces high-quality parts regardless of polyethylene type.

PE Injection Molding Custom Solutions: Matching Density to Application Needs

Our PE injection molding services offer custom solutions that precisely match polyethylene density to your application’s unique requirements. We collaborate with clients to understand functional needs, then recommend HDPE or LDPE formulations—including custom blends with additives like UV stabilizers, colorants, or antimicrobial agents—to enhance performance. For custom HDPE parts, we design complex geometries with integrated features like threads, hinges, and mounting points that leverage the material’s strength. For LDPE customization, we create flexible designs with living hinges, snap-fit closures, and ergonomic grips that utilize the material’s elasticity. Our design team uses 3D modeling to optimize part geometry for the selected density, ensuring manufacturability while meeting performance goals. Whether modifying an existing design or developing a new part, our PE injection molding custom solutions balance density characteristics with functional requirements for optimal results.

PE Injection Molding Quality Assurance: Consistent Performance Across Densities

Quality assurance is integral to our PE injection molding services, ensuring consistent performance across both HDPE and LDPE parts. We implement rigorous testing protocols specific to each density: for HDPE, we verify tensile strength, impact resistance, and chemical compatibility; for LDPE, we test flexibility, elongation at break, and seal integrity. Our quality team uses automated inspection systems to check dimensional accuracy, ensuring parts meet specifications regardless of density. We also conduct material verification for every production run, confirming resin density, melt flow rate, and additive content to maintain consistency. For critical applications, we perform environmental testing—including UV exposure for outdoor parts and thermal cycling for temperature-sensitive components—to validate performance. This comprehensive quality assurance ensures our PE injection molding delivers HDPE and LDPE parts that consistently meet or exceed performance expectations, regardless of density or application.