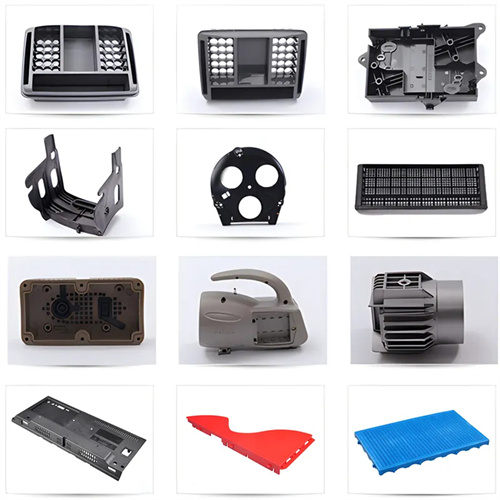

ABS Injection Molding Excellence: The Foundation of Overmolding & Insert Molding Services

At our facility, we build our ABS overmolding and insert molding services on a foundation of injection molding excellence, delivering enhanced performance and durability for complex plastic components. Overmolding and insert molding are advanced techniques that expand ABS’s capabilities by combining it with other materials or metal inserts, creating parts with superior functionality. Our expertise in ABS injection molding ensures seamless integration between layers or components, as we understand how ABS bonds with elastomers, metals, or other plastics under precise molding conditions. We recognize that modern applications demand more than single-material parts—they require combinations that offer grip, shock absorption, electrical conductivity, or structural reinforcement. That’s why our team leverages decades of injection molding experience to master these techniques, ensuring every overmolded or insert-molded part maintains dimensional stability and long-term reliability. From concept to production, we prioritize precision to create components that outperform single-material alternatives in durability and performance.

ABS Injection Molding Synergy: How Overmolding Enhances Material Performance

Our ABS overmolding services thrive on the synergy between ABS and other materials, enhancing overall part performance through strategic material combinations. Overmolding involves injecting a second material—often a soft elastomer like TPE or TPU—over a pre-molded ABS substrate, creating a single part with both rigid structural support and flexible functionality. This process capitalizes on ABS’s excellent adhesion properties, ensuring the two materials bond permanently without delamination, even under repeated stress or temperature changes. The rigid ABS core provides strength and shape retention, while the overmolded layer adds features like ergonomic grips, impact resistance, or chemical resistance. We carefully control molding parameters such as temperature, pressure, and cooling to optimize adhesion, ensuring the final part acts as a unified structure rather than separate components. This approach eliminates assembly steps, reduces part counts, and creates products that are more durable than multi-piece alternatives, making them ideal for tools, medical devices, and consumer electronics.

ABS Injection Molding Precision: The Role of Insert Molding in Structural Integrity

Insert molding, a key offering in our ABS injection molding services, enhances structural integrity by embedding metal or plastic inserts directly into ABS components during the molding process. This technique eliminates the need for post-assembly steps like screwing, gluing, or press-fitting, creating stronger, more reliable bonds between inserts and the ABS matrix. We work with various inserts, including threaded fasteners, metal rods, electrical contacts, and circuit boards, strategically placing them in molds before injecting molten ABS. The ABS flows around the inserts, conforming to their shape and creating a mechanical lock that resists vibration, torque, and pull-out forces—far exceeding the strength of assembled alternatives. Our precision mold design ensures inserts are positioned accurately, avoiding defects like misalignment or flash that could compromise performance. By integrating inserts during molding, we produce parts that maintain consistent dimensions, reduce weight, and improve durability, making them perfect for automotive components, industrial machinery, and electrical enclosures.

ABS Injection Molding Customization: Tailoring Overmolding & Insert Molding to Unique Needs

Our ABS injection molding services excel in customizing overmolding and insert molding solutions to meet unique industry and application needs. We understand that every project has specific requirements, whether it’s a medical device needing a soft, latex-free grip over an ABS housing or an automotive part requiring metal inserts for structural reinforcement. Our engineering team collaborates with clients to select the ideal materials, design mold geometries, and determine insert placements that optimize performance. For overmolding, we offer a range of compatible materials, from food-grade elastomers to flame-retardant compounds, ensuring the final part meets regulatory standards and functional demands. For insert molding, we source high-quality inserts and design molds that accommodate their dimensions while ensuring proper ABS flow. This customization extends to production volumes, as we seamlessly scale from prototyping small batches to mass-producing millions of parts, all while maintaining consistent quality and performance.

ABS Injection Molding Quality: Ensuring Reliability in Overmolded & Insert-Molded Parts

Quality is paramount in our ABS overmolding and insert molding services, as these complex parts often play critical roles in safety-critical or high-performance applications. We implement rigorous quality control measures throughout the production process, starting with material inspections to verify ABS resin purity and the compatibility of overmolding materials or inserts. During molding, advanced sensors monitor temperature, pressure, and cycle times in real-time, alerting our team to any deviations that could affect part integrity. Post-production, each batch undergoes thorough testing, including adhesion strength tests for overmolded parts and pull-out force evaluations for insert-molded components. We also check for dimensional accuracy, ensuring inserts are properly positioned and overmolded layers have uniform thickness. Adhering to standards like ISO 13485 for medical applications and IATF 16949 for automotive parts, we guarantee that every part meets strict performance and safety criteria, giving clients confidence in their durability and reliability.

ABS Injection Molding Partnerships: Driving Innovation Through Collaborative Solutions

At the heart of our ABS overmolding and insert molding services is a commitment to building collaborative partnerships that drive innovation. We view clients as partners, working closely with their design and engineering teams to solve complex challenges and unlock new possibilities for part performance. Our technical experts provide guidance on material selection, mold design, and process optimization, helping clients reduce costs, improve efficiency, and enhance product durability. Whether it’s developing a ergonomic tool handle with overmolded grip or a lightweight electronic enclosure with metal inserts, we bring creativity and precision to every project. We also invest in advanced molding technology, from multi-cavity molds to automated insert placement systems, ensuring we can handle the most complex designs with consistency. By choosing our ABS injection molding services for overmolding and insert molding, clients gain a partner dedicated to delivering enhanced performance, durability, and innovation that drives their products’ success in competitive markets.