Hydraulic core pullers are a crucial mechanism for complex lateral core pulling in injection molds. Their advantages, including high core pulling force, controllable stroke, and smooth movement, make them widely used in large plastic parts or complex core pulling scenarios. However, their design requires coordination between the hydraulic system and the mold structure. Failure to carefully consider these factors can easily lead to unstable core pulling, oil leakage, and low efficiency. Therefore, the design of hydraulic core pullers must consider multiple factors, including power matching, structural strength, and safety protection, to ensure long-term stability and reliability.

Designing the dynamic parameters for hydraulic core pulling is a primary consideration. The key lies in matching the cylinder selection with the core pulling force and distance. The core pulling force must be calculated based on the part’s undercut dimensions, the plastic’s shrinkage rate, and the friction coefficient. A safety factor of 1.5-2 times is typically required to prevent damage to the cylinder due to sudden excessive loads. For example, for large, undercut PP parts, the core pulling force must account for the combined force of the melt’s clamping force on the core and frictional resistance. If the calculated value is 50kN, the cylinder’s rated output force should be no less than 75kN. The core pulling distance must be 5-10mm greater than the undercut depth to ensure complete release of the part from the core. A 5-10mm cushion should be added to the cylinder stroke to prevent impact when the piston reaches its limit. Furthermore, the cylinder’s operating pressure must be compatible with the injection molding machine’s hydraulic system, generally maintained at 8-16MPa. Excessively high pressure can lead to seal degradation, while excessively low pressure may result in insufficient power.

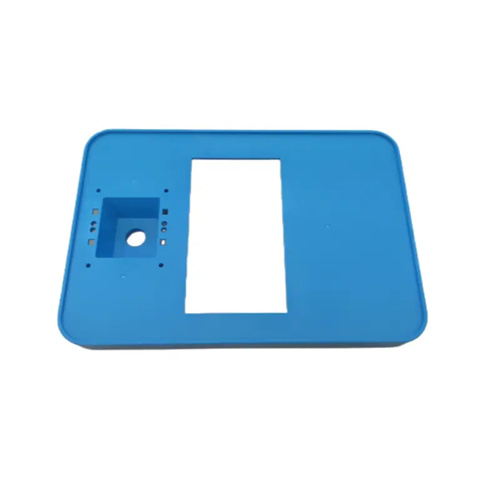

The structural layout of the hydraulic core pulling must avoid interference with other parts of the mold, while ensuring the accuracy of the core movement trajectory. The installation position of the cylinder should be close to the core pulling direction, shortening the lever arm to reduce the bending moment and prevent the core from bending and deforming. If there is an offset between the core pulling direction and the cylinder axis, the movement direction must be converted through a connecting rod or gear mechanism, and the clearance of the transmission components must be controlled within 0.02-0.05mm to avoid cumulative errors affecting the core pulling accuracy. The core and the guide sleeve are matched with an H7/f6 clearance fit, and the guide length is not less than 2 times the core diameter to ensure smooth movement. For oblique or arc-shaped core pulling, a special guide rail must be designed, the radius of curvature of which is consistent with the undercut arc of the plastic part, and the surface must be nitrided to improve wear resistance.

The sealing and protective design of the hydraulic system directly impacts the lifespan of the core-pulling mechanism. High-pressure seals, such as polyurethane U-rings or combination seals, are required at the connection between the cylinder and the oil circuit. Static seals should use an O-ring plus retaining ring structure to prevent hydraulic oil leakage and contamination of the mold or plastic parts. For multi-cavity molds or complex core-pulling systems, one-way valves and throttle valves are required in the main oil circuit to achieve independent control and speed adjustment of each core-pulling unit to avoid interference caused by pressure fluctuations. Furthermore, the mold must have protective grooves for the oil passage to prevent wear on the oil pipes during core movement. Exposed hydraulic components must be equipped with dust covers to prevent plastic debris or cooling water from entering the cylinder.

The synchronization and safety interlock design of hydraulic core pulling cannot be ignored, especially in scenarios where multiple sets of core pulling work together. When a mold has multiple hydraulic core pulling units, the movement speed of each cylinder needs to be adjusted through a flow control valve to ensure that the core pulling and reset actions are synchronized, with a deviation of no more than 0.5mm, to prevent deformation of the plastic parts due to uneven force. The safety interlock needs to be linked to the injection molding machine control system through a stroke switch. Injection is prohibited when the core pulling is not in place, and mold closing is prohibited when the reset is not completed, to avoid mold collisions due to misoperation. For example, in the multi-directional core pulling design of a car bumper mold, 5 sets of stroke sensors need to be set to provide real-time feedback on the position of each core to ensure that mold closing is allowed only after all units are reset.

Hydraulic core pullers’ maintenance-friendly design can reduce ongoing maintenance costs. The cylinder should be removable to facilitate seal replacement. Standard quick-change connectors should be used for oil line connections during mold installation. Vulnerable parts such as guide sleeves and seals should be removable, and spare parts should be readily available. Furthermore, the oil system should be equipped with a filter with a filter accuracy of at least 10μm to prevent impurities from entering the cylinder and scratching the inner wall. Molds that are not used for extended periods should have their hydraulic oil drained to prevent oxidation and blockage of the oil lines. Through proper maintenance planning, the mean time between failures of hydraulic core pullers can be extended to over 5,000 mold cycles.