Injection nozzle casting and solution

Injection nozzle flow refers to the phenomenon of continued plastic melt flowing out of the nozzle of an injection molding machine after injection has stopped, commonly known as “drooling.” This phenomenon not only wastes raw material but also contaminates the mold parting surface and nozzle. It can even cause cold material to enter the mold cavity, impacting product quality and causing defects such as cold material spots and material shortages. Flow often occurs during molding processes using low-viscosity plastics (such as PE and PP) or high melt temperatures. It is primarily related to nozzle structure, process parameters, and raw material characteristics. Long-term neglect of flow issues can lead to equipment failures such as nozzle blockage and mold corrosion. Therefore, it is important to promptly analyze the cause and implement targeted solutions.

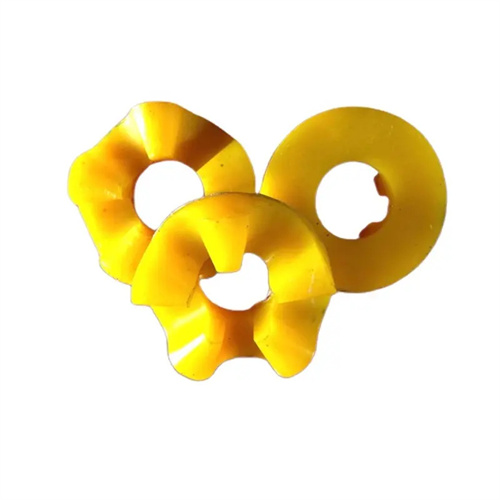

Improper injection molding nozzle design is a major cause of casting. The nozzle’s aperture, length, and check mechanism are particularly crucial in preventing casting. If the nozzle aperture is too large, the melt can easily flow out of the nozzle due to gravity and residual pressure. Generally, the nozzle aperture should be selected based on the part weight and plastic viscosity. A φ2-3mm aperture is recommended for small parts, while a φ4-6mm aperture is recommended for large parts. Avoid excessively large nozzles. Excessively long nozzles increase the amount of melt retained within the nozzle, making it difficult to quickly release residual pressure, leading to casting. A nozzle that is too short can cause poor fit with the mold sprue bushing, increasing the risk of leakage. The check mechanism is crucial. Conventional open nozzles lack a sealing mechanism, making casting highly susceptible to occur. However, spring-loaded or hydraulically controlled check nozzles quickly close the channel after injection, preventing melt from flowing out. For example, the clearance between the check ring and the nozzle head should be controlled within 0.01-0.03mm to ensure a seal without affecting melt flow during injection.

Improper process parameter settings are the primary cause of flow casting, with melt temperature, back pressure, and holding pressure parameters having the most significant impact. Excessively high melt temperature reduces plastic viscosity, increasing melt fluidity and making flow casting more likely within the nozzle. For example, when the melt temperature of PP exceeds 230°C, flow casting is significantly exacerbated. Therefore, the barrel temperature should be set appropriately based on the plastic’s characteristics. While maintaining fluidity, the melt temperature should be kept as low as possible. For example, the melt temperature of PE can be controlled between 180-200°C, avoiding excessively high temperatures. Excessive back pressure causes the melt pressure within the barrel to remain high for extended periods. After injection, residual pressure cannot be quickly released, leading to melt overflow from the nozzle. Back pressure should generally be controlled between 5-15 bar, with the lower limit being used for low-viscosity plastics. Excessively long holding times or high holding pressures can also lead to flow casting. The holding parameters should be adjusted based on the thickness of the part to ensure timely pressure relief after the melt solidifies. For thin-walled parts, for example, the holding time can be shortened to 2-3 seconds to reduce residual pressure accumulation.

The properties of the plastic raw material directly impact nozzle casting. Low-viscosity, high-flow plastics are more susceptible to casting. The melt flow rate ( MFR) of different plastics varies significantly. A higher MFR value indicates better flow but a greater risk of casting. For example, PP with an MFR of 20g/10min is more susceptible to casting than PP with an MFR of 5g/10min. This lower melt viscosity makes it more difficult to maintain stability within the nozzle. Excessive impurities or additives in the raw material can also affect melt stability. Excessive amounts of certain lubricants can reduce melt cohesion and exacerbate casting. Furthermore, excessive raw material humidity can cause water vaporization within the barrel, creating bubbles that disrupt melt continuity and increase the risk of casting. Therefore, targeted measures need to be taken according to the characteristics of the raw materials: for low-viscosity plastics, thickeners can be appropriately added to increase the viscosity; for raw materials that are easy to flow, special nozzles with a check structure should be selected; at the same time, the dryness of the raw materials must be strictly controlled. For example, the moisture content of PA plastics must be lower than 0.05% to avoid flow caused by water vapor.

Addressing flow-through in injection molding nozzles requires a comprehensive approach encompassing equipment modification, process optimization, and standardized operating procedures. Replacing conventional open nozzles with closed, check-type nozzles is the most effective measure. For example, a spring-return check-type nozzle features an internal check ring that quickly rebounds after injection, shutting off the melt flow path. For older equipment, a throttle valve can be installed at the nozzle tip to manually or automatically close the flow path and prevent flow. Regarding process optimization, in addition to reducing melt temperature and back pressure, a “delayed release after injection” technique can be employed. This involves waiting 1-2 seconds after injection before releasing the screw. This allows the melt in the nozzle to initially cool and solidify, reducing the amount of flow. Furthermore, the release amount and speed should be adjusted. The release amount is generally 3-5mm, and the speed should be kept low to prevent air entrapment and bubbles. Regarding standardized operating procedures, residual melt in the nozzle should be emptied before each shutdown. This can be done by manually injecting the melt, then turning off the heating device to prevent continued flow at high temperatures within the nozzle.

Long-term casting will cause a series of derivative problems, which need to be prevented from worsening through regular maintenance and monitoring. If the cast cold material accumulates between the nozzle and the mold gate, it will lead to poor sealing of the mold parting surface, flash when the mold is closed, and even damage the mold; after the cold material enters the cavity, it will form hard spots, affecting the strength of the product, especially in the stress-bearing parts, which may become a source of fracture. Therefore, it is necessary to clean the nozzle and gate sleeve every shift, and use a copper brush to remove residual cold material to avoid accumulation. Regularly check the sealing performance of the non-return nozzle. If the non-return ring is found to be worn or the spring is found to be failed, it must be replaced in time to ensure that the sealing gap meets the requirements. During the production process, the nozzle casting situation can be monitored by installing an infrared sensor. Once an abnormality is found, an alarm will be immediately triggered, and the loosening or cooling program will be automatically started to reduce raw material waste and equipment damage. The above comprehensive measures can effectively solve the nozzle casting problem and improve production stability and product quality.