Injection Molding Brittleness and Solutions

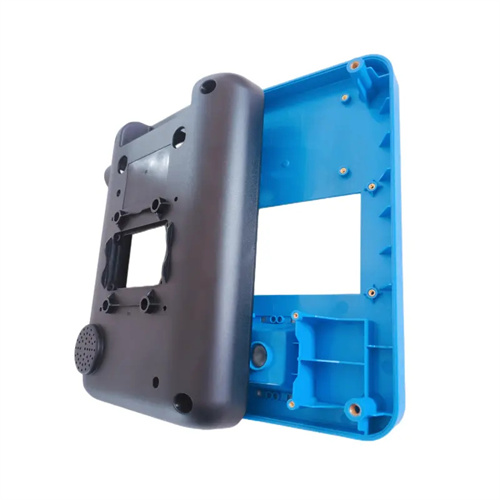

Injection molding brittleness refers to the phenomenon that plastic parts show decreased mechanical properties, insufficient toughness, and are prone to cracks or fractures after molding, which not only affects the service life of the product, but may also cause safety hazards. This defect is particularly obvious in low temperature environments or under stress. For example, the edges and corners of home appliance casings may break due to excessive brittleness during assembly, and children’s toys may produce small fragments due to brittleness, posing a risk of accidental swallowing. The causes of injection molding brittleness are complex, involving multiple links such as raw material characteristics, process parameters, and mold design. For example, insufficient toughening agent content in the raw materials, melt degradation, and excessive cooling may all cause plastic parts to become brittle. Solving this problem requires systematic analysis and taking measures in multiple dimensions from material selection, process optimization to mold improvement to effectively improve the toughness and impact resistance of plastic parts.

Raw material properties and formulation design are fundamental factors affecting the toughness of plastic parts. Improper material selection or formulation defects can easily lead to brittleness. First, the toughness of base resins varies significantly. For example, polystyrene (PS) is inherently brittle, while polyethylene (PE) and polypropylene (PP) are more brittle. Using PS in load-bearing parts can easily lead to brittleness. For plastic parts requiring high toughness, copolymer resins (such as ABS and PC/ABS alloys) or modified plastics with toughening agents should be selected. For example, adding 5%-10% ethylene propylene rubber to PP can increase impact strength by 2-3 times. Impurities in raw materials or an excessive proportion of recycled material can also contribute to brittleness. After repeated processing, recycled material breaks down its molecular chains, degrading its performance. It is recommended that the recycled material content should not exceed 30%, and that it be thoroughly mixed with virgin material. Furthermore, excessive amounts of lubricants or stabilizers can weaken intermolecular forces, leading to brittle plastic parts. For example, adding more than 0.5% zinc stearate can reduce the impact strength of ABS parts by over 15%, necessitating strict control of additive dosage.

Improper process parameter settings are a major cause of brittleness during injection molding. Optimizing melting, injection, and cooling parameters is crucial for improving part performance. Excessively high melt temperatures can lead to raw material degradation, molecular chain breakage, and reduced part toughness. For example, when the melt temperature of PC exceeds 320°C, thermal degradation and brittleness can occur. The temperature should be controlled between 280-300°C. Excessively fast injection speeds can cause excessive shearing of the melt, generating significant internal stress. Especially for high-viscosity plastics (such as PC and PMMA), medium-to-low injection speeds (30-50 mm/s) should be used to avoid forced stretching of the molecular chains. Excessively high holding pressures or prolonged holding times can lead to internal stress concentration in the part, making it more susceptible to brittleness after cooling. The holding pressure should be controlled at 60%-70% of the injection pressure, and the holding time should be extended by 1-2 seconds after the cavity is fully filled. Too fast a cooling speed will lead to uneven crystallization inside the plastic part (for crystalline plastics) or excessive internal stress. The mold temperature needs to be adjusted according to the type of plastic. For example, the mold temperature of PP should be controlled at 40-60℃, and that of ABS should be controlled at 60-80℃ to ensure that the plastic part cools slowly and reduces internal stress.

Improper mold design can exacerbate the brittleness of plastic parts, requiring structural optimization to reduce stress concentration and uneven cooling. First, sharp corners and sudden changes in wall thickness within the part structure are stress concentration points and can easily become the starting point for brittle fracture. All internal corners should be rounded with a radius of at least 0.5mm, and the wall thickness difference should be controlled within a 2:1 ratio. Reinforced ribs should be used for transitions when necessary. The location and size of the gate affect the melt flow path. If the gate is too small (diameter less than 1mm), the melt will be sheared severely during passage, leading to localized degradation. The gate diameter should be determined based on the thickness of the part, typically 0.5-1 times the wall thickness. Uneven distribution of the mold cooling system can cause localized cooling of the part too quickly. For example, the lack of cooling water channels on ribs or bosses can cause rapid cooling and brittleness in these areas. Ensure that the cooling water channels are 15-25mm from the cavity surface and are evenly distributed. In addition, forced demolding caused by improper design of the demolding mechanism will generate mechanical stress and aggravate brittleness. It is necessary to ensure sufficient draft angle (≥1°) and ejection area to avoid excessive local stress.

Post-processing and quality control of plastic parts are supplementary measures to address brittleness, effectively eliminating internal stress and improving toughness. Annealing is an effective method for eliminating internal stress. Placing the plastic part in an oven, holding it at 10-20°C above its glass transition temperature for 2-4 hours, and then slowly cooling it to room temperature can reduce internal stress by over 50%. For example, annealing PC parts at 120-130°C for 3 hours can increase their impact strength by 20%, while annealing ABS parts at 80-90°C for 2 hours significantly relieves internal stress. For brittleness caused by minor degradation, surface treatment (such as applying an elastic coating) can compensate for performance deficiencies, but this cannot completely resolve the problem, and process parameters must be controlled at the source. During quality testing, regular testing of plastic part toughness through impact tests (such as Izod and Simple Beam) is required to ensure that the impact strength meets design requirements. Batches with a brittleness defect rate exceeding 5% should be halted for investigation and cause determination. Through comprehensive optimization of materials, processes, and molds, combined with post-processing measures, the brittle defect rate of plastic parts can be controlled below 1%, significantly improving product quality stability.