Injection molded thermal water channel

Injection molding thermal conductive water channels are a core component of the mold cooling system. By opening channels inside the mold cavity and core to allow the introduction of media such as cooling water or hot oil, precise temperature control of the mold is achieved, thereby affecting the molding quality and production efficiency of the plastic part. Compared with traditional cooling water channels, thermal conductive water channels focus more on improving heat exchange efficiency through optimized structural design and material selection, ensuring rapid and uniform cooling of the melt, and reducing deformation and internal stress in the plastic part. This type of water channel is widely used in various types of injection molds and is particularly indispensable in the production of large, complex plastic parts, thin-walled plastic parts, and high-precision plastic parts. For example, by using high-efficiency thermal conductive water channels, the cooling time of a mobile phone casing mold can be shortened from 20 seconds to 12 seconds, increasing production efficiency by 40%. The design of the thermal conductive water channel must be combined with the shape of the plastic part, the properties of the plastic, and the molding process to achieve a balance between cooling speed and uniformity.

The structural design of injection molding heat transfer channels directly impacts their heat transfer efficiency. Common configurations include straight-through, wraparound, stepped, and cascaded. Straight-through channels offer a simple structure and are suitable for flat-plate parts. They consist of several parallel straight channels connected by inlet and outlet nozzles. While their advantages include ease of processing, their disadvantages include poor cooling uniformity, making them suitable for applications with less demanding cooling requirements. Wraparound channels, distributed along the contour of the part, take a ring or U-shape. They are suitable for round or irregularly shaped parts, such as cup molds. These channels encircling the mold cavity provide more uniform cooling, keeping the temperature differential within ±3°C. Stepped channels are used for parts with varying thicknesses. Channel depth and diameter are adjusted based on the thickness of different regions of the part. Thick-walled areas use channels with larger diameters (10-12mm) and closer to the mold cavity (15-20mm). Thin-walled areas use channels with smaller diameters (6-8mm) and further away (20-25mm), ensuring consistent cooling rates across all areas. Conformal water channels are currently the most advanced structure. Using 3D printing technology, they are created to perfectly fit the surface of the plastic part, ensuring that the distance between the cooling medium and the cavity surface is uniform everywhere (usually 15-20mm). This is particularly suitable for complex curved plastic parts, such as automobile bumper molds. Using conformal water channels can shorten the cooling time of plastic parts by 30% and reduce deformation by 50%.

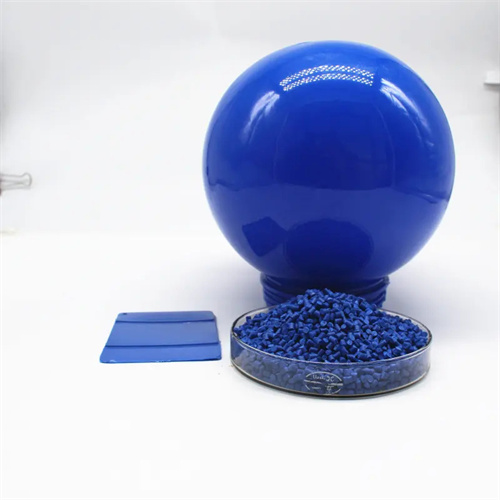

The material selection and processing of thermally conductive water channels significantly impact thermal conductivity. The mold cavity and water channel inserts must be made of materials with excellent thermal conductivity. Commonly used materials include S136 (thermal conductivity 16W/(m・K) ), 718H (thermal conductivity 25W/(m・K) ), and beryllium copper (thermal conductivity 200W/(m・K) ). For areas with high cooling requirements (such as near the gate), beryllium copper inserts can be used to quickly dissipate heat through their high thermal conductivity. For example, the use of beryllium copper water channel inserts around the gate of a PC transparent plastic mold increased cooling speed by three times, effectively reducing sink marks near the gate. The machining process for water channels is determined by the structural form. Straight and stepped water channels can be machined using a drill press, while wraparound water channels require wire EDM or milling. Flexible water channels rely on 3D printing technology (such as SLM (Selective Laser Melting)). Metal powder (such as 316 stainless steel or tool steel) is printed layer by layer with an accuracy of ±0.1mm. The roughness of the water channel’s inner wall must be controlled below Ra1.6μm. A smooth inner wall reduces flow resistance, increases flow velocity (1-3m/s), and enhances heat transfer efficiency. Burrs or depressions on the inner wall can cause localized turbulence and scaling, affecting cooling effectiveness.

The fluid dynamics design of the heat transfer water channel is crucial for ensuring cooling efficiency, including parameters such as water velocity, flow rate, pressure, and media selection. The water flow must reach a turbulent state (Reynolds number > 4000) for efficient heat transfer. Typically, the required flow rate is 1.5-3 m/s. For large-diameter channels (10-12 mm), the flow rate can be reduced to 1.5-2 m/s, while for small-diameter channels (6-8 mm), the flow rate should be increased to 2-3 m/s. The flow rate is determined by the total volume of the water channel. The flow rate should reach 1-2 L/min per meter of water channel. For example, for a 10-meter water channel system, the total flow rate should be controlled at 10-20 L/min. The pressure differential between the inlet and outlet water should be maintained at 0.1-0.3 MPa to ensure stable water flow. Excessive pressure can damage mold seals, while excessively low pressure can affect flow rate. The choice of cooling medium depends on the type of plastic and mold temperature requirements. For ordinary plastic parts, cooling water (5-25°C) is sufficient. For crystalline plastics (such as PP and PA), a mold temperature controller is required to control the mold temperature (40-80°C), using hot water or hot oil for precise temperature control. Furthermore, the water quality must meet standards, with a hardness of less than 50 mg/L (measured as CaCO3) to prevent scale accumulation and clogging of the waterways. Filters and softening devices can be installed in the cooling system, and the coolant should be replaced regularly.

Optimizing and maintaining thermally conductive water channels is crucial for ensuring long-term, efficient operation. During the design phase, CAE simulation software (such as Moldflow) can be used to analyze the cooling effect of the water channels. The temperature distribution of the plastic part under different water channel configurations can be simulated to identify hotspots (areas where the temperature is more than 5°C above the average). This can then be used to increase the number of water channels or adjust their location accordingly. For example, CAE analysis revealed a hotspot at a corner of a TV housing mold. Adding an 8mm diameter branch water channel reduced the hotspot temperature by 7°C. During use, the water channels must be cleaned regularly to remove scale and impurities from the inner walls. Chemical cleaning (such as citric acid solution) or physical cleaning (such as high-pressure water jets) can be used. The cleaning cycle is determined by water quality and production batch size (typically every three months). For complex water channels, such as those with irregular shapes, ultrasonic cleaning can be used to remove internal dirt through high-frequency vibration. Furthermore, the water channels must be inspected for leaks. A hydraulic pressure test (1-1.5 MPa, hold pressure for 30 minutes) must be performed before mold assembly to ensure leaks. If cooling efficiency is found to be declining, check the water pump flow rate, thermostat accuracy, and water channel blockages, and replace any damaged components promptly. Through continuous optimization and maintenance, the heat transfer efficiency of the thermal conductive water channel can be maintained at over 90% of its initial state, ensuring consistent plastic part quality.