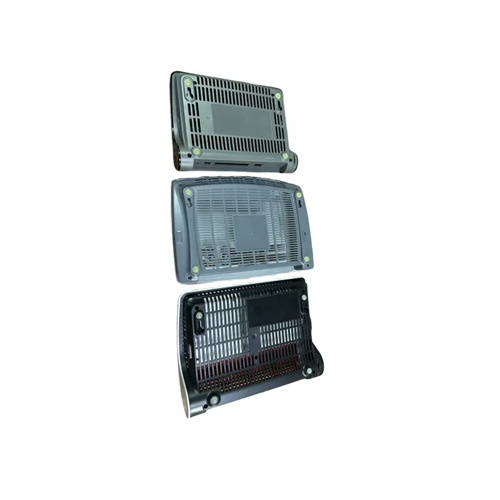

Improvement measures for weld marks and water ripples in PVC injection molded parts

PVC (polyvinyl chloride), a low-cost plastic material with diverse properties, is widely used in injection molding. However, during the production process, PVC injection molded parts are prone to cosmetic defects such as weld marks and water ripples. These defects not only affect the product’s aesthetics but can also weaken the part’s structural strength, leading to problems such as cracking during use. Weld marks are lines formed when the melt fails to fully merge after being diverted and reunited within the mold cavity. Water ripples appear as irregular, wave-like patterns on the surface of the molded part. Both are closely related to the PVC material properties, mold design, and process parameters, requiring targeted measures to improve them.

A thorough understanding of PVC material properties is fundamental to resolving weld mark and moire issues. PVC resin has a narrow melting temperature range (typically 160-190°C). When temperatures exceed 200°C, it decomposes easily, releasing hydrogen chloride gas. This reduces melt fluidity, and the decomposition products can contaminate the mold, exacerbating defects. PVC melts also have high viscosity, making their fluidity sensitive to temperature and shear rate. Temperature or pressure fluctuations during the injection molding process can easily lead to unstable melt flow, resulting in moire. Furthermore, PVC injection molding typically requires the addition of additives such as plasticizers and stabilizers. The type and ratio of these additives affect the compatibility and fluidity of the melt. If the additives are unevenly dispersed, localized viscosity differences can occur during melt flow, leading to weld marks or moire. Therefore, selecting the appropriate PVC grade (such as general-purpose PVC with an average degree of polymerization between 800-1000) and supporting additives, and ensuring their uniform mixing, are essential for addressing cosmetic defects.

The rationality of mold design directly impacts the molding quality of PVC injection molded parts. Optimizing mold structure is crucial for reducing weld marks and water ripples. The location and number of mold gates are particularly important for preventing weld marks. Improper gate placement results in excessively long melt diversion paths or a narrow convergence angle (less than 90°). The melt temperature drops significantly upon convergence, making it difficult to fully fuse, resulting in noticeable weld marks. To address this, minimize the number of melt diversions and place gates where the part walls are thicker or the melt flow path is shorter to ensure the melt temperature remains high upon convergence. For large or complex parts, increase the number of gates appropriately, shorten the length of individual weld marks, and distribute weld marks on non-exterior surfaces or areas with less stress. Furthermore, a cold slug well should be placed at the melt convergence point to collect cold slugs from the front of the low-temperature stream, preventing them from entering the convergence area and reducing the visibility of weld marks.

To address the issue of water ripples, the mold’s runner design requires optimization. Water ripples are often caused by poor melt flow within the runners or by irregular melt accumulation on the cavity surface due to sudden changes in flow velocity. Therefore, runners should have larger diameters (typically 8-12mm for main runners and 5-8mm for branch runners) to reduce resistance to melt flow. Runner transitions should be rounded (with a radius of no less than 3mm) to avoid pressure loss and flow velocity fluctuations caused by right-angle turns. Furthermore, the mold’s exhaust system must be improved. If the cavity is poorly vented, gas pressure will hinder the uniform advancement of the melt front, causing the melt to accumulate in a wave-like pattern on the cavity surface, creating water ripples. Venting grooves with a depth of 0.02-0.03mm and a width of 5-10mm should be installed in the final filling area of the cavity and at the melt flow transition points to ensure smooth gas discharge and maintain smooth melt flow.

Precise control of process parameters is the key to improving the appearance of defects in PVC injection molded parts. To address weld marks, parameters must be adjusted to increase the temperature and pressure at the time of melt convergence. The barrel temperature should be appropriately raised (160-170°C in the front section, 170-180°C in the middle section, and 150-160°C in the back section) to maintain good melt fluidity. Simultaneously, the injection pressure (typically 60-90 MPa) and injection speed should be increased to accelerate melt flow, reduce heat loss, and ensure that the melt remains at a relatively high temperature at convergence, promoting diffusion and fusion between molecules. The holding pressure and holding time should also be appropriately set: 60%-70% of the injection pressure, and 5-15 seconds depending on the thickness of the part. This continuous pressure replenishment compacts the weld mark area and reduces the visibility of the defect.

The key to addressing water ripples is to stabilize the melt flow and avoid sudden changes in flow rate and pressure. Controlling the injection speed is particularly important, and a staged injection method should be used: initially, inject the melt smoothly into the runner at a low speed (10-20 mm/s) to avoid vortexes caused by high-speed impact. After entering the cavity, gradually increase the speed (30-50 mm/s) to ensure uniform filling of the cavity. Once the cavity is approximately 90% filled, reduce the speed again to prevent the melt front from impacting the cavity wall due to inertia, forming ripples. Mold temperature control is also crucial. Mold temperatures for PVC injection molding are typically set between 30-50°C. If the temperature is too low, the melt will cool and solidify rapidly on the cavity surface, making it difficult for the subsequent melt to fuse with the solidified layer, potentially leading to water ripples. If the temperature is too high, the cooling time will be prolonged, resulting in part deformation. Heaters or a hot oil circulation system can be installed on the mold cavity surface to ensure a uniform and stable surface temperature, promoting smooth melt flow and solidification.

In addition, raw material pretreatment and equipment maintenance can also affect the effectiveness of defect improvement. PVC raw materials need to be dried before injection molding (temperature 60-80°C, time 2-4 hours) to remove moisture from the raw materials and prevent bubbles from evaporating, which can cause overlapping defects such as weld marks and water ripples. Regarding equipment, the barrel and screw must be cleaned regularly to prevent residual PVC decomposition products from contaminating the new material and affecting melt fluidity. The sealing of the check ring and nozzle should be checked to avoid pressure fluctuations caused by backflow during melting and ensure the stability of the injection process. Through mold optimization, fine-tuning of process parameters, and strict control of the production process, the weld marks and water ripples of PVC injection molded parts can be effectively improved, improving the product’s appearance quality and performance.