In the vibrant and creative toy industry, POM injection molding has emerged as a game – changing technology, empowering us to produce toys that combine exceptional durability, precise functionality, and captivating designs. By leveraging the unique properties of polyoxymethylene (POM) and the precision of injection molding processes, we can create toy components that meet the diverse needs of children and collectors alike, ensuring both safety and endless hours of play. POM injection molding is revolutionizing the way we manufacture toys, driving innovation and enhancing the overall quality of our products.

1. The Material Benefits of POM Injection Molding for Toys

When we set out to manufacture toys, the choice of POM for injection molding is driven by its outstanding material characteristics. POM boasts high mechanical strength and rigidity, making it an ideal material for toys that endure rough handling and frequent use. Its excellent tensile strength allows POM – injection – molded toy parts to resist deformation and breakage, even when subjected to strong pulling, twisting, or dropping forces that are common in children’s play. For example, in construction toys, POM – molded connectors and building blocks can maintain their shape and structural integrity, enabling children to build sturdy and complex structures without the pieces easily breaking.

Another remarkable property of POM is its low coefficient of friction. This feature is particularly beneficial for toys with moving parts, such as toy cars with wheels, action figures with articulated joints, or toy trains with rolling mechanisms. POM – injection – molded wheels and axles ensure smooth movement, allowing toy vehicles to glide effortlessly across various surfaces. The smooth operation not only enhances the play experience but also reduces wear and tear on the parts, extending the lifespan of the toys. Additionally, POM has good chemical resistance, which means it can withstand exposure to common substances like saliva, sweat, and cleaning agents, ensuring the hygiene and durability of toys that are often in close contact with children.

2. POM Injection Molding in Building Block Toys

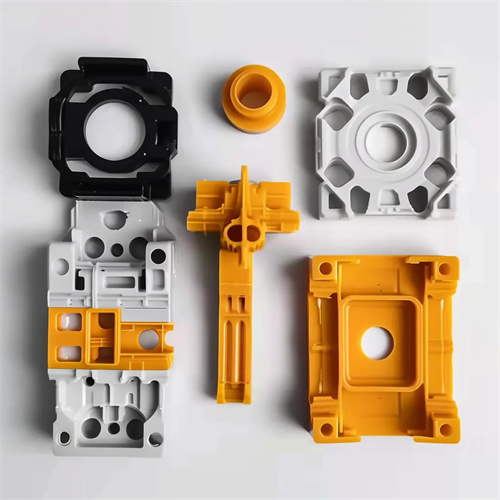

Building block toys are a staple in the toy industry, and POM injection molding has significantly enhanced their quality and playability. The precision of POM injection molding allows us to create building blocks with exacting dimensions, ensuring a perfect interlocking fit between each piece. Whether it’s traditional square – shaped blocks or more specialized shapes like arches, slopes, and gears, POM – injection – molded blocks provide a consistent and reliable connection, enabling children to build stable and elaborate structures.

We can also take advantage of POM’s durability to make the blocks more resistant to wear and tear. The high – strength material ensures that the blocks can withstand repeated assembly and disassembly without losing their shape or functionality. Moreover, the smooth surface finish achievable through POM injection molding gives the blocks an attractive appearance and a pleasant tactile feel, enhancing the overall play experience. Some POM – molded building blocks can even be designed with textured surfaces to mimic different materials, adding an extra layer of realism and creativity to children’s play.

3. POM Injection Molding in Action Figures and Dolls

For action figures and dolls, POM injection molding plays a crucial role in creating high – quality and durable components. When manufacturing the bodies, limbs, and accessories of action figures, POM – injection – molded parts offer excellent strength and flexibility. The joints of action figures, in particular, benefit from POM’s low coefficient of friction, allowing for a wide range of poses and smooth movement. Children can easily manipulate the action figures to recreate their favorite scenes from movies, cartoons, or their own imaginative stories.

In dolls, POM – injection – molded parts can be used for various elements, such as hands, feet, and facial features. The precision of the injection molding process enables us to create detailed and realistic features, from the delicate fingers of a doll’s hand to the expressive eyes on its face. POM’s chemical resistance also ensures that the doll’s components remain unaffected by common substances that may come into contact during play, maintaining their appearance and integrity over time.

4. Precision and Cost – Efficiency of POM Injection Molding in Toy Production

Precision is at the heart of our POM injection molding processes for toy production. Advanced injection molding machines, equipped with state – of – the – art computer – controlled systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing small and intricate toy components, like the tiny buttons on a toy phone, the wheels of a miniature toy vehicle, or the fasteners on a toy playset, we can fine – tune the injection process to achieve extremely tight tolerances. For example, the dimensions of POM – injection – molded toy wheels can be produced with an accuracy of ±0.01mm, ensuring a perfect fit and smooth rotation.

Cost – efficiency is another significant advantage of POM injection molding in toy production. Although the initial investment in mold development for complex toy designs can be substantial, the long – term benefits far outweigh the costs. The mass – production capabilities of injection molding enable us to produce POM – molded toy parts at a relatively low cost per unit. When manufacturing 100,000 POM – injection – molded building blocks in a single batch, for instance, the cost per piece can be minimized through economies of scale. The automated nature of the process also reduces labor costs, as computer – controlled machines handle most of the production tasks, minimizing the risk of human – error – related defects.

5. Future Prospects of POM Injection Molding in the Toy Industry

As we look to the future, we are excited about the potential of POM injection molding in the toy industry. With the growing emphasis on sustainability, we anticipate the development of more eco – friendly POM – based materials. Researchers may focus on creating bio – based POM or improving the recyclability of POM – molded toy components, reducing the environmental impact of toy production. This will not only meet the increasing consumer demand for green products but also contribute to a more sustainable future for the toy industry.

Advancements in technology will also open up new possibilities for POM injection molding in toys. We expect to see more integration of smart features into toys, and POM – injection – molded parts could play a role in housing sensors, LED lights, or sound – emitting devices. These features will add an interactive and educational element to toys, enhancing children’s learning and play experiences. Additionally, improvements in mold – making technology, such as 3D printing for mold prototyping, will allow us to create more customized and innovative POM – injection – molded toys more quickly, keeping up with the ever – changing trends and demands of the toy market.