As professionals deeply involved in the packaging industry, we have witnessed firsthand how ABS injection molding has transformed our manufacturing processes and the final products we deliver. This versatile manufacturing technique has become an indispensable part of our toolkit, enabling us to create packaging solutions that are not only durable and functional but also aesthetically appealing. From protecting delicate consumer goods to enhancing brand visibility on store shelves, ABS injection molding has proven its worth across a wide range of packaging applications.

1. The Fundamentals of ABS Injection Molding in Packaging

In the realm of packaging, ABS injection molding begins with the careful selection of Acrylonitrile Butadiene Styrene pellets. These pellets are fed into a hopper, which then transports them to a heated barrel. Inside the barrel, a combination of external heating, typically set between 200°C and 260°C, and the mechanical action of a rotating screw melts the ABS material into a viscous liquid. Once in a molten state, the screw injects the ABS under high pressure, usually ranging from 70 to 150 megapascals, into a precisely designed mold cavity.

The mold, often crafted from high – quality steel or aluminum, is customized according to the specific requirements of the packaging product. For instance, when creating a packaging enclosure for a high – end electronic device, the mold is designed with compartments to securely hold the device and its accessories, as well as features for easy opening and closing. After the mold is filled, a cooling system within the mold rapidly cools the ABS, causing it to solidify and take on the exact shape of the mold cavity. Once fully cooled, the mold opens, and the finished ABS packaging component is ejected, ready for further assembly, decoration, or direct use.

2. Design Flexibility Enabled by ABS Injection Molding

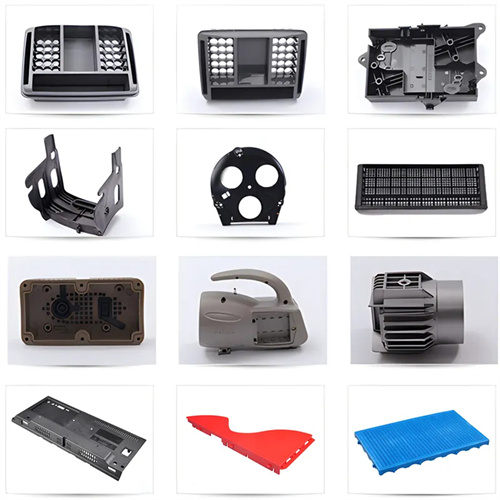

One of the most significant advantages of ABS injection molding in the packaging industry is its unparalleled design flexibility. Unlike traditional packaging materials and manufacturing methods, ABS injection molding allows us to bring even the most intricate and innovative designs to life. We can create packaging with complex geometries, such as curved surfaces, sharp angles, and detailed textures, which are often difficult or impossible to achieve with other techniques.

For example, in a recent project for a luxury cosmetics brand, we were tasked with designing a unique packaging case for a new line of products. Using ABS injection molding, we were able to create a packaging case with a sleek, organic shape that resembled a gemstone. The case featured smooth, flowing lines and a highly polished surface, which not only protected the cosmetics inside but also served as a powerful marketing tool, attracting consumers on the store shelves. Additionally, we can easily incorporate functional elements into the design, such as snap – fit closures, hinges, and locking mechanisms, all in a single molding process, enhancing the usability and convenience of the packaging.

3. Durability and Protection Offered by ABS Injection Molding

In the packaging industry, ensuring the safety and integrity of the products being packaged is of utmost importance. ABS injection molding provides us with packaging solutions that offer exceptional durability and protection. The high impact resistance of ABS makes it ideal for safeguarding delicate and valuable items during transportation and handling. Our tests have shown that ABS – molded packaging can withstand drops from significant heights without cracking or breaking, effectively protecting the contents inside.

Moreover, ABS has excellent chemical resistance, which is crucial when packaging products that may come into contact with various substances. For instance, when packaging chemicals, pharmaceuticals, or food products, ABS packaging can resist the corrosive effects of these substances, preventing leaks and contamination. This chemical stability also ensures that the packaging maintains its structural integrity over time, even when exposed to different environmental conditions, such as varying temperatures and humidity levels.

4. Cost – effectiveness of ABS Injection Molding in Packaging

In a highly competitive packaging market, cost – effectiveness is a key factor in our business success, and ABS injection molding offers significant cost – saving opportunities. While the initial investment in mold creation for ABS injection molding can be relatively high, especially for complex designs, the long – term benefits far outweigh the upfront costs. Once the mold is fabricated, the injection molding process can produce large quantities of identical packaging components with minimal material waste and labor requirements.

For example, when producing packaging trays for a consumer electronics company, a single mold can produce thousands of trays per day. The economies of scale achieved through high – volume production reduce the per – unit cost of the packaging significantly. Additionally, the ability to integrate multiple functions into a single ABS – molded part, such as handles, compartments, and protective features, eliminates the need for additional assembly steps and components, further reducing production costs. This cost – effectiveness allows us to offer competitive pricing to our customers while maintaining high – quality standards.

5. Future Prospects of ABS Injection Molding in Packaging

Looking ahead, we are excited about the future prospects of ABS injection molding in the packaging industry. As technology continues to advance, we anticipate further improvements in the properties of ABS materials. Researchers are working on developing new formulations of ABS that are more lightweight, yet still maintain their excellent strength and durability. A lighter – weight ABS would not only reduce material costs but also lower transportation costs, as lighter packaging means lower fuel consumption during shipping.

In addition, the integration of smart technologies into packaging is an emerging trend. We envision using ABS injection molding to create packaging with embedded sensors or RFID tags, which can provide real – time information about the product, such as its temperature, location, and freshness. This would be particularly valuable for industries such as food and pharmaceuticals, where product safety and traceability are critical. Furthermore, with the growing focus on sustainability, we are exploring ways to incorporate recycled ABS materials into our injection molding processes, reducing our environmental impact while still meeting the high – quality requirements of the packaging industry.