In the rapidly evolving landscape of LED lighting, POM injection molding has emerged as a game – changing technology, enabling us to manufacture components that combine outstanding mechanical properties, durability, and precision. By leveraging the unique characteristics of polyoxymethylene (POM) and the capabilities of injection molding, we can create parts that meet the stringent requirements of modern LED lighting products, from enhancing component functionality to ensuring long – term reliability. POM injection molding plays an increasingly vital role in driving innovation and improving the overall quality of LED lighting solutions.

1. The Material Advantages of POM Injection Molding for LED Lighting

When we embark on the production of LED lighting products, the choice of POM for injection molding is based on its remarkable material properties. POM, also known as acetal, offers excellent mechanical strength, stiffness, and wear resistance. Its high tensile strength allows it to withstand mechanical stress, making it ideal for components that need to maintain their shape and structural integrity over time. In LED lighting, POM – injection – molded parts can resist deformation even under continuous operation and varying environmental conditions.

Another significant advantage of POM is its low coefficient of friction. This property is crucial for components that require smooth movement, such as adjustable LED light fixtures. POM – injection – molded joints and hinges can move freely without excessive friction, ensuring easy adjustment and long – lasting performance. Additionally, POM has good chemical resistance, which means it can withstand exposure to common cleaning agents and environmental pollutants, protecting the LED lighting components from degradation and ensuring their durability in different usage scenarios.

2. POM Injection Molding in LED Lighting Component Manufacturing

POM injection molding is widely used in the manufacturing of various LED lighting components. One of the key applications is in the production of LED heat sink brackets. POM’s high stiffness and dimensional stability enable us to create brackets with precise shapes and dimensions, ensuring a perfect fit for heat sinks and LED modules. These brackets can effectively support the heat – dissipating elements, facilitating the transfer of heat away from the LED chips and maintaining their optimal operating temperature, which is essential for the lifespan and performance of the LEDs.

In LED light bulb bases, POM – injection – molded parts provide reliable electrical insulation and mechanical support. The excellent electrical insulating properties of POM prevent electrical leakage, ensuring the safety of users. At the same time, its mechanical strength allows the base to securely hold the LED bulb in place, withstanding the forces applied during installation and use. For LED strip light connectors, POM injection molding enables the production of components with precise snap – fit mechanisms, ensuring a secure connection between LED strips and facilitating easy installation and maintenance.

3. Precision and Efficiency of POM Injection Molding for LED Lighting

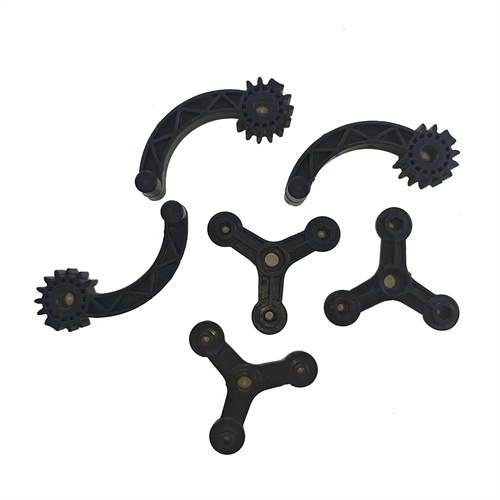

Precision is at the core of our POM injection molding processes for LED lighting. Advanced injection molding machines, equipped with sophisticated computer – controlled systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing small and intricate POM components, like the tiny gears in LED adjustable spotlights, we can fine – tune the injection process to achieve extremely tight tolerances. For example, the dimensions of these gears can be produced with an accuracy of ±0.01mm, ensuring smooth and precise operation of the spotlight’s adjustment mechanism.

The efficiency of POM injection molding is also remarkable. Once we optimize the mold design and set the appropriate molding parameters, we can achieve high – speed production. In a large – scale production line for POM – injection – molded LED bulb bases, the automated process can produce 1800 units per hour while maintaining consistent quality. The repeatability of the process not only streamlines our production operations but also reduces the time and cost associated with quality control, as each POM – molded part meets our strict standards with minimal variation.

4. Cost – Effectiveness of POM Injection Molding in LED Lighting Production

Cost – effectiveness is a crucial factor in LED lighting production, and POM injection molding offers significant advantages in this regard. Although the initial investment in mold development for POM injection molding may be relatively high, especially for complex designs, the long – term benefits far outweigh the costs. The mass – production capabilities of injection molding enable us to produce POM parts at a relatively low cost per unit. When manufacturing 80,000 POM – injection – molded LED heat sink brackets in a single batch, for instance, the cost per piece can be minimized through economies of scale.

The automated nature of the POM injection molding process also helps in reducing labor costs. With computer – controlled machines handling most of the production tasks, we require fewer operators, minimizing the risk of human – error – related defects. Additionally, the high precision and durability of POM – molded parts reduce the need for frequent replacements and repairs, further cutting down on long – term maintenance costs. By optimizing the design for manufacturability and streamlining production processes, we can offer high – quality LED lighting products with POM components at competitive prices.

5. Future Prospects of POM Injection Molding in the LED Lighting Industry

As we look to the future, we are excited about the prospects of POM injection molding in the LED lighting industry. With the continuous demand for more energy – efficient, intelligent, and sustainable LED lighting solutions, we anticipate further exploration of POM’s potential. Researchers are likely to develop new POM – based materials with enhanced properties, such as improved thermal conductivity and better compatibility with other materials, which will open up new possibilities for LED lighting design and performance optimization.

The integration of smart features into LED lighting products will also present new opportunities for POM injection molding. We expect to embed sensors, microcontrollers, and wireless communication modules into POM – injection – molded components, enabling features like remote control, ambient light sensing, and energy management. Additionally, as sustainability becomes an even more critical issue, efforts will be made to improve the recyclability of POM – molded parts, contributing to a more circular economy in the LED lighting industry. These future developments will undoubtedly expand the applications and influence of POM injection molding in shaping the next – generation LED lighting products.