In the highly competitive and demanding field of hardware tool manufacturing, PP injection molding has emerged as a transformative technology, enabling us to produce components that combine durability, functionality, and cost – effectiveness. By leveraging the unique properties of polypropylene (PP) and the precision of injection molding processes, we can create parts that meet the diverse needs of professional craftsmen, DIY enthusiasts, and industrial applications. PP injection molding is playing an increasingly significant role in enhancing the quality and performance of hardware tools, driving innovation in the industry.

1. The Material Properties of PP Injection Molding for Hardware Tools

When we engage in the production of hardware tools, the choice of PP for injection molding is based on its remarkable material attributes. PP offers excellent chemical resistance, which is crucial for hardware tools that may come into contact with various substances during use, such as oils, solvents, and cleaning agents. For example, in automotive repair tools, PP – injection – molded parts can resist the corrosive effects of motor oils and degreasers, ensuring the longevity of the tools.

Another important property of PP is its good impact resistance. Hardware tools often endure accidental drops, impacts, and rough handling. PP – injection – molded components can withstand these forces without cracking or breaking, providing reliable protection for the internal structures and mechanisms of the tools. Additionally, PP has a relatively low density, making it a lightweight material. This characteristic reduces the overall weight of hardware tools, making them more portable and easier to handle, especially for tools that require extended use or are used in mobile applications. Moreover, PP exhibits good electrical insulation properties, which are beneficial for tools that may be used near electrical sources, preventing electrical shocks and ensuring user safety.

2. PP Injection Molding in Tool Handle Manufacturing

Tool handles are a critical component that directly affects the usability and comfort of hardware tools, and PP injection molding has revolutionized their production. We can create ergonomic handles with precise contours and textures using PP injection molding. By analyzing the natural grip and movement patterns of the human hand, we design handles that fit comfortably, distributing the force evenly and reducing hand fatigue during prolonged use. For instance, in the case of a handheld power drill, the PP – injection – molded handle can be shaped to conform to the palm’s curvature, providing a secure and comfortable hold even during high – torque operations.

The injection molding process also allows us to incorporate features such as anti – slip patterns into the handles. These patterns can be molded with varying degrees of roughness, ensuring a firm grip even in wet or oily conditions. Additionally, we can add color and branding elements during the molding process, making the tool handles not only functional but also visually appealing and easily recognizable. The durability of PP ensures that the handles can withstand the rigors of daily use, including impacts, drops, and exposure to harsh environmental conditions.

3. PP Injection Molding for Tool Storage and Organization

Efficient storage and organization are essential for hardware tools, and PP injection molding offers excellent solutions in this regard. We produce a wide range of tool storage products, such as toolboxes, trays, and organizers, using PP injection molding. PP – molded toolboxes are lightweight yet durable, providing reliable protection for tools during transportation and storage. They can withstand impacts, drops, and rough handling, ensuring the safety of the tools inside. The high strength of PP also allows for the creation of toolboxes with strong latches and hinges that can securely hold the lid in place.

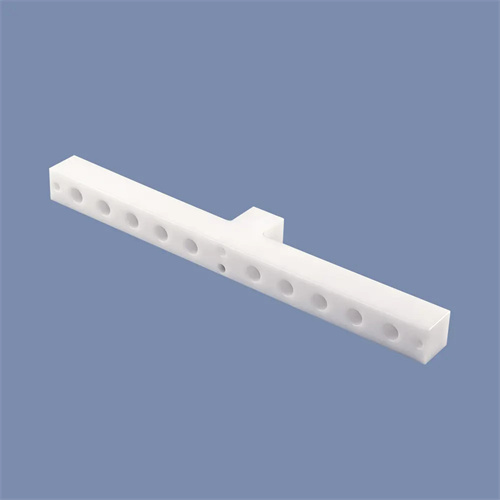

PP – injection – molded trays and organizers are designed with customized compartments and dividers to fit specific tools and components. For example, in a mechanic’s toolbox, we create trays with precisely sized slots for wrenches, sockets, and screwdrivers, keeping them neatly arranged and easily accessible. The smooth surfaces of these POM parts also make them easy to clean, preventing the accumulation of dirt and debris that could interfere with tool functionality. Moreover, the modular design of PP – injection – molded storage solutions allows users to customize their tool storage according to their specific needs.

4. Precision and Cost – Efficiency of PP Injection Molding in Hardware Tool Production

Precision is at the core of our PP injection molding processes for hardware tool production. Advanced injection molding machines, equipped with sophisticated computer – controlled systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing small and intricate components, like the tiny screws and nuts used in tool assemblies or the delicate parts of tool mechanisms, we can fine – tune the injection process to achieve extremely tight tolerances. For example, the dimensions of PP – injection – molded small parts can be produced with an accuracy of ±0.01mm, ensuring a perfect fit and seamless operation of the tools.

Cost – efficiency is another significant advantage of PP injection molding. Although the initial investment in mold development for complex hardware tool designs can be substantial, the long – term benefits far outweigh the costs. The mass – production capabilities of injection molding enable us to produce PP parts at a relatively low cost per unit. When manufacturing 10,000 PP – injection – molded tool clips in a batch, for instance, the cost per piece can be significantly reduced through economies of scale. The automated nature of the process also reduces labor costs, as computer – controlled machines handle most of the production tasks, minimizing the risk of human – error – related defects.

5. Future Prospects of PP Injection Molding in the Hardware Tool Industry

As we look to the future, we are excited about the potential of PP injection molding in the hardware tool industry. With the increasing focus on sustainability, we anticipate the development of more eco – friendly PP – based materials. Researchers may focus on creating bio – based PP or improving the recyclability of PP – molded parts, reducing the environmental impact of hardware tool production. This will not only meet the growing demand for green products but also contribute to a more sustainable manufacturing process.

Advancements in technology will also open up new possibilities for PP injection molding. We expect to see more integration of smart features into hardware tools, and PP – injection – molded parts could play a role in housing sensors, RFID tags, and other intelligent components. These features will enable functions such as tool tracking, inventory management, and usage monitoring, enhancing the efficiency and productivity of both professional and DIY users. Additionally, improvements in mold – making technology, such as 3D printing for mold prototyping, will allow us to create more customized and innovative PP – injection – molded hardware tool components more quickly, meeting the evolving needs of the market.