As manufacturers deeply involved in the hardware tools industry, we have discovered that ABS injection molding is a game – changer in our production processes. This innovative manufacturing technique has become an indispensable part of our toolkit, enabling us to produce high – quality, durable, and user – friendly hardware tools. From hand tools like pliers and wrenches to power tool accessories, ABS injection molding offers a wide range of benefits that enhance both the functionality and market competitiveness of our products.

1. The Core Process of ABS Injection Molding in Hardware Tools

The application of ABS injection molding in hardware tool production starts with the careful selection of ABS pellets. These pellets are fed into the hopper of an injection molding machine, which then conveys them to a heated barrel. Inside the barrel, the temperature is precisely controlled, usually set between 200°C and 260°C, to melt the ABS material into a molten state. As the rotating screw within the barrel mixes and pressurizes the molten ABS, it reaches a consistency suitable for injection.

Once in the optimal state, the molten ABS is injected under high pressure, typically ranging from 70 to 150 megapascals, into a mold cavity designed according to the specific requirements of the hardware tool component. For example, when manufacturing the handle of a screwdriver, the mold is crafted with ergonomic contours for a comfortable grip, non – slip textures, and attachment points for the metal shaft. After injection, a cooling system integrated into the mold rapidly cools the ABS, causing it to solidify and take on the exact shape of the mold cavity. Once fully cooled, the mold opens, and the finished ABS component is ejected, ready for assembly with other parts of the hardware tool.

2. Design Innovation Enabled by ABS Injection Molding

One of the most significant advantages of ABS injection molding in the hardware tools industry is its ability to drive design innovation. It allows us to break free from the limitations of traditional manufacturing methods and create tools with unique and practical designs. For instance, in the production of pliers, we can use ABS injection molding to create handles with complex geometries that fit perfectly in the user’s hand, reducing hand fatigue during prolonged use.

We can also integrate multiple functions into a single ABS – molded part. In the case of power tool accessories, such as drill bit holders, we can mold in compartments for different sizes of drill bits, locking mechanisms to keep the bits secure, and identification markings for easy selection. Moreover, ABS injection molding enables us to customize the color and texture of the tool components. By adding color masterbatches during the molding process, we can create tools with distinct colors for better brand recognition or color – coding for different functions.

3. Performance Enhancement through ABS Injection Molding

ABS injection molding significantly enhances the performance of our hardware tools. ABS has excellent impact resistance, which is crucial for tools that are often subjected to accidental drops or impacts during use. Our tests have shown that tools with ABS – molded handles can withstand impacts from a height of 1.5 meters without cracking or breaking, protecting the internal structure and ensuring the safety of the user.

Furthermore, ABS offers good chemical resistance, making it suitable for tools that may come into contact with various substances, such as lubricants, solvents, or cleaning agents. For example, wrenches with ABS – coated surfaces can resist the corrosive effects of these substances, maintaining their appearance and functionality over time. Additionally, ABS has good thermal properties, allowing it to withstand the heat generated during intense tool use without deforming, ensuring the long – term reliability of the hardware tools.

4. Cost – efficiency Achieved by ABS Injection Molding

In the highly competitive hardware tools market, cost – efficiency is essential for our business success, and ABS injection molding provides us with significant cost – saving opportunities. While the initial investment in mold creation for ABS injection molding can be substantial, especially for complex tool designs, the long – term benefits far outweigh the upfront costs.

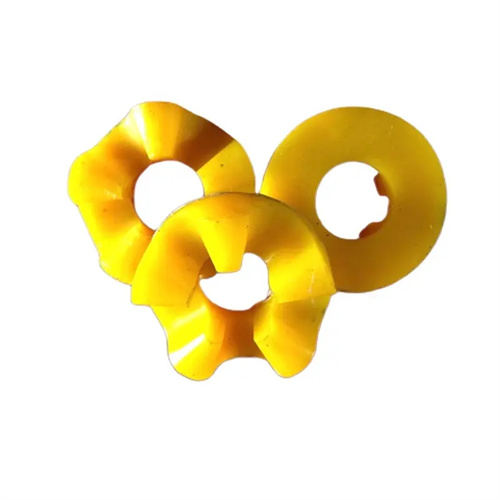

Once the mold is fabricated, the injection molding process can produce large quantities of identical components with minimal material waste. For example, when manufacturing plastic caps for hardware tool storage cases, a single mold can produce thousands of units per day. The economies of scale achieved through high – volume production reduce the per – unit cost of the components significantly. Additionally, by integrating multiple functions into a single ABS – molded part, we can eliminate the need for additional assembly steps and components, reducing labor costs and production time. The consistent quality of ABS injection – molded parts also minimizes the need for post – production rework, further contributing to cost savings.

5. Future Prospects of ABS Injection Molding in Hardware Tools

Looking to the future, we are excited about the potential of ABS injection molding in the hardware tools industry. As technology continues to evolve, we anticipate several advancements. Researchers are working on developing new formulations of ABS with enhanced properties, such as increased strength – to – weight ratio and better wear resistance. These improved materials will enable us to create lighter, more durable hardware tools that offer better performance.

In addition, the integration of advanced manufacturing technologies, such as 3D printing and smart manufacturing systems, with ABS injection molding is on the horizon. 3D printing can be used for rapid prototyping of new tool designs, reducing the time and cost associated with traditional design iterations. Smart manufacturing systems will allow for real – time monitoring and optimization of the injection molding process, improving product quality and production efficiency. Furthermore, with the growing focus on sustainability, we expect to see an increased use of recycled ABS materials in hardware tool production, reducing our environmental impact while maintaining the high – quality standards of our products.