In the dynamic realm of electrical product manufacturing, PET (Polyethylene Terephthalate) injection molding has become an indispensable technology, enabling us to create components that are both high – performance and reliable. This manufacturing process combines the unique properties of PET material with precise molding techniques, offering a wide array of benefits from enhancing electrical insulation to ensuring product durability. As we strive to meet the evolving demands of the electrical industry, PET injection molding continues to play a crucial role in shaping the quality and functionality of our products.

1. The Material Attributes of PET Injection Molding for Electrical Products

When we choose PET injection molding for electrical products, we leverage the material’s outstanding characteristics. PET’s excellent electrical insulation properties are of utmost importance. It effectively prevents the flow of electrical current, ensuring the safety of users and the proper functioning of electrical components. In the production of electrical connectors, for example, PET – molded insulators can withstand high voltages without breaking down, providing a reliable barrier between conductive parts. Laboratory tests have shown that PET can maintain its insulation integrity even at voltages exceeding 5000 volts, making it a trusted choice for our high – voltage electrical applications.

The mechanical strength of PET also contributes significantly to the durability of electrical products. It can withstand the rigors of assembly, handling, and transportation without deforming or cracking. In the case of electrical enclosures, PET – molded housings protect the internal components from physical damage, such as impacts and vibrations. These enclosures can endure forces equivalent to being dropped from a height of 1.2 meters without compromising the integrity of the enclosed electrical parts, ensuring the long – term reliability of our products in various environments.

2. Precision and Quality Control in PET Injection Molding Processes for Electrical Products

Precision is at the core of our PET injection molding operations for electrical products. Advanced injection molding machines, equipped with sophisticated control systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing small electrical components, like miniature circuit breakers, we can fine – tune the injection pressure to ensure that the molten PET fills the mold cavity uniformly and accurately. This level of control enables us to create components with tight tolerances; for instance, the dimensions of PET – molded terminal blocks can be achieved with an accuracy of ±0.02mm, ensuring a perfect fit with other electrical parts.

Quality control is a continuous process in our production. We implement strict inspection procedures at every stage, from mold design to the final product. Using advanced imaging and measurement technologies, we can detect even the slightest defects in the PET – molded components. For example, X – ray inspection helps us identify internal voids or inconsistencies in the material, while optical profilometry ensures the surface finish and dimensional accuracy meet our high standards. By maintaining such rigorous quality control, we can minimize the occurrence of defective products, reducing costs associated with rework and product recalls.

3. Design Adaptability Enabled by PET Injection Molding in Electrical Products

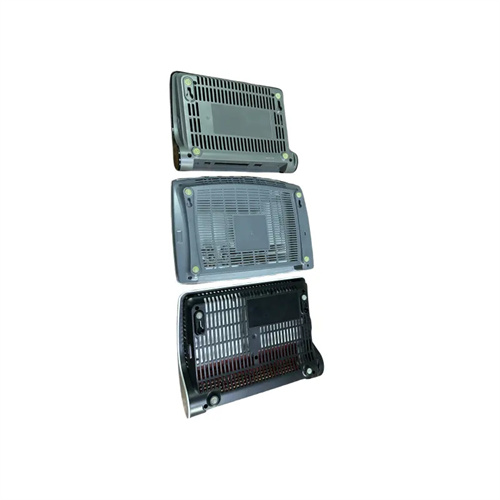

PET injection molding provides us with remarkable design flexibility in electrical product manufacturing. We can create components with complex geometries tailored to the specific requirements of different electrical devices. For smart home appliances, we can mold PET into sleek, compact shapes that house intricate electrical circuits and sensors, while also providing an aesthetically pleasing exterior. The ability to incorporate various textures and finishes into the PET – molded parts further enhances the product’s visual appeal and user experience.

Customization is another significant advantage. We can choose from a wide range of colors by adding color masterbatches during the molding process, allowing us to match the product design with the brand’s color scheme or the intended application environment. Additionally, we can integrate functional features directly into the PET – molded components. For example, we can design heat – dissipating ribs or mounting bosses, which not only improve the performance of the electrical product but also simplify the assembly process.

4. Cost – Efficiency of PET Injection Molding in Electrical Product Production

Cost – efficiency is a key consideration in our electrical product production using PET injection molding. Although the initial investment in mold development can be substantial, especially for complex designs, the long – term benefits far outweigh the costs. The mass – production capabilities of PET injection molding enable us to reduce the cost per unit significantly. When producing 100,000 PET – molded electrical switch covers in a single batch, the cost per piece can be as low as $0.15, making it a highly cost – effective option compared to other manufacturing methods.

The automated nature of the injection molding process also contributes to cost savings. With computer – controlled machines handling most of the production tasks, we require fewer operators, reducing labor costs. Moreover, the high precision and consistency of the process minimize the occurrence of defective products. In our production facilities, the defect rate of PET – molded electrical components is less than 1%, which reduces the expenses related to rework, scrap, and product recalls. By optimizing the design for manufacturability and using efficient production techniques, we can offer high – quality electrical products at competitive prices.

5. Future Trends of PET Injection Molding in the Electrical Product Industry

Looking ahead, we are excited about the future prospects of PET injection molding in the electrical product industry. As technology continues to advance, there is an increasing demand for smaller, more powerful, and energy – efficient electrical products. We anticipate further improvements in PET material properties, such as enhanced thermal conductivity, which would enable better heat dissipation in high – power electrical devices. This could lead to more compact and efficient designs, reducing the overall size and weight of electrical products.

The integration of smart technologies is another trend we expect to see. We plan to embed sensors, microcontrollers, and wireless communication modules directly into PET – molded components, enabling features such as remote monitoring, self – diagnosis, and intelligent control. Additionally, as sustainability becomes an even more critical factor, we are committed to developing more eco – friendly PET formulations, such as bio – based PET, which would reduce the environmental impact of our electrical products. These advancements will not only expand the capabilities of PET injection molding in the electrical product industry but also drive innovation and progress in the field.