The injection molding demolding system is a key mechanism in the injection mold used to separate the formed plastic part from the cavity or core. It comes in a variety of forms and must be selected based on factors such as the part’s structure, material, and shape to ensure smooth demolding without compromising quality. Common injection molding demolding systems include push rod demolding, push tube demolding, push block demolding, ejector plate demolding, and inclined ejector demolding. Each form has its own unique structural characteristics and scope of application. In actual production, it is necessary to flexibly apply them, and sometimes a combination of multiple forms is needed to meet complex plastic part demolding requirements.

The push rod demoulding system is the most widely used form, with the advantages of simple structure, easy manufacturing, and low cost. It consists of parts such as a push rod, a push rod fixing plate, a push plate, a guide pin and a guide sleeve. During operation, the push rod directly applies the ejection force to the appropriate part of the plastic part, causing the plastic part to be released from the mold. The push rod demoulding system is suitable for plastic parts of various shapes, especially small and medium-sized plastic parts and plastic parts with relatively simple structures, such as housings and cover plates. However, due to the small contact area between the push rod and the plastic part, it is easy to leave ejection marks on the surface of large plastic parts or plastic parts with high surface quality requirements. In this case, it is necessary to use other demoulding methods in conjunction with it. When designing the push rod demoulding system, the position and number of the push rods must be reasonably arranged to ensure that the ejection force is evenly distributed to avoid deformation or damage to the plastic parts.

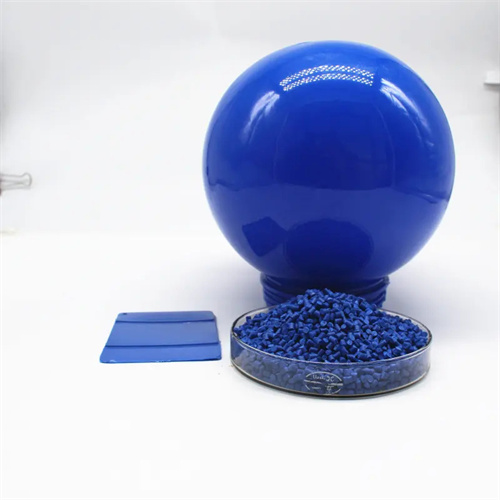

The push-tube demolding system is primarily suitable for cylindrical, annular, or tubular plastic parts with a center hole, such as bottle caps, bearing sleeves, and pipe fittings. Its structure is similar to that of a push-rod demolding system, but the push rod is replaced by a push-tube. The push-tube is tubular and fits over the outside of the core. During operation, the push-tube moves along the axis of the core to eject the plastic part from the core. The large contact area between the push-tube and the plastic part allows for evenly distributed ejection force, effectively preventing deformation of the plastic part and leaving no noticeable ejection marks on the inner wall of the part, thus ensuring the surface quality and dimensional accuracy of the part. The push-tube demolding system requires high precision in the fit between the core and the push-tube, requiring strict control of the gap between the two to prevent melt overflow while ensuring smooth movement of the push-tube.

The top plate demoulding system, also known as the ejector plate demoulding system, is suitable for large flat-plate plastic parts, thin-walled plastic parts, or plastic parts with complex shapes and high demoulding resistance, such as automobile dashboards and large housings. It consists of a top plate, a push rod, a push rod fixing plate, etc. The top plate has a large contact area with the plastic part, which can provide uniform ejection force and effectively prevent problems such as warping and deformation of the plastic part during the demoulding process. The ejection action of the top plate demoulding system is smooth and reliable, and is particularly suitable for plastic parts with high surface quality requirements. Because the top plate has a large contact surface with the plastic part, the pressure per unit area is low, and it is less likely to leave ejection marks on the surface of the plastic part. However, the structure of this system is relatively complex, the mold manufacturing cost is high, and it requires a large installation space, so it is rarely used in small molds.

The inclined ejector system is mainly used for plastic parts with undercuts or side holes, such as those with protrusions, grooves, threads, and other structures. It uses the oblique movement of the inclined ejector pin to simultaneously eject the plastic part and complete the lateral core pulling action, allowing the plastic part to be smoothly released from the undercut area. The inclined ejector system consists of a inclined ejector pin, a guide slider, a push rod, a return spring, and other parts. During operation, the push plate drives the inclined ejector pin to move upward. Due to a certain inclination angle between the inclined ejector pin and the mold, lateral displacement occurs during the upward movement, achieving the dual functions of core pulling and ejection. The inclined ejector system has a compact structure and smooth movements, which can effectively solve the demolding problem of the undercut area of plastic parts. However, it has high requirements for the processing accuracy and assembly of the parts, and the inclined ejector pin must ensure flexible movement to avoid jamming or wear. In actual applications, the inclined ejector system is often used in combination with other demolding methods to meet the demolding needs of complex plastic parts.