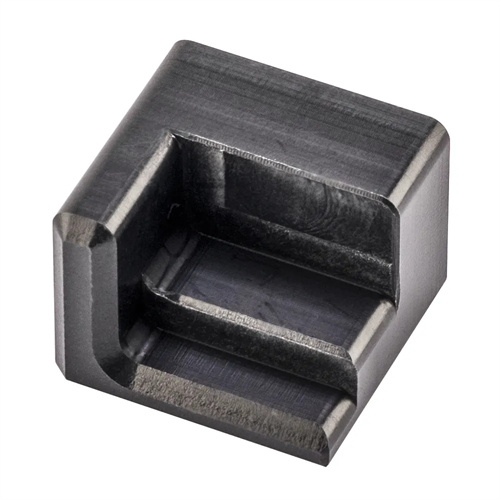

Structure of injection mold frame

The injection mold frame is the basic framework of the injection mold, acting as the mold’s “skeleton,” supporting the mold’s various functional components and ensuring their precise fit and stable operation during the injection molding process. The mold frame’s structural design directly affects the mold’s assembly accuracy, service life, and molding efficiency, and therefore plays a vital role in mold design. A complete injection mold frame typically consists of core components such as the fixed mold base plate, movable mold base plate, fixed platen, movable platen, guide posts, guide sleeves, support posts, ejector plate, and ejector fixing plate. These components are assembled together with connectors such as bolts and pins to form a rigid whole, providing installation references and motion guides for the mold cavity, core, and ejector mechanism.

The fixed and movable mold bases form the upper and lower bases of the injection mold frame, connected to the injection molding machine’s fixed and movable mold plates, respectively, to withstand the clamping force and injection pressure during the injection molding process. The fixed mold base is typically located above the mold, and its surface requires positioning holes and mounting screws to ensure precise positioning of the mold on the injection molding machine. The movable mold base, located below, connects to the injection molding machine’s ejector mechanism, providing a fulcrum for power transmission. The thickness and material of these two bases are selected based on the mold size and clamping force. They are generally made of high-quality carbon structural steels such as 45 steel or S50C, which undergo a tempering process to enhance their strength and rigidity and prevent deformation during stress.

The fixed platen and movable platen are key components in the mold frame for mounting the cavity and core, and are also the main parts that form the closed cavity when the mold is closed. The fixed platen is fixed to the fixed mold base, and is usually embedded with the female mold (cavity) inside. The movable platen is guided by the movable mold base through guide pins and guide sleeves, and is installed with the male mold (core) inside. During the injection molding process, the fixed platen and movable platen are precisely clamped together under the drive of the injection molding machine. The cavity and core form the molding space of the product. The molten material fills the cavity under pressure and is cooled and formed. The two templates have extremely high requirements for flatness and parallelism, and usually need to undergo precision grinding to ensure the sealing performance during mold closing and prevent molten material leakage. At the same time, the templates also need to be processed with structures such as guide pin holes, ejector pin holes, and cooling water channels to meet functional requirements such as guiding, ejection, and cooling.

Guide pins and guide sleeves are the “guiding system” that ensures the accuracy of mold opening and closing. The accuracy of their fit directly affects the working stability of the mold and the quality of the product. Guide pins are usually fixed to the movable or fixed mold plate, are cylindrical, and their surfaces are quenched and precision-ground, with high hardness and surface roughness. The guide sleeves are embedded in the corresponding template holes, forming a clearance fit with the guide pins, guiding the template to move in the correct direction during the mold opening and closing process to avoid collisions between the cavity and the core. There are many ways to arrange guide pins and guide sleeves, the most common ones are four-corner symmetrical arrangement and diagonal arrangement. For large molds or molds with higher precision requirements, auxiliary guide pins are added to improve guiding accuracy. In addition, the length of the guide pins needs to be long enough to ensure that part of the guide pin remains in the guide sleeve when the mold is fully opened to prevent the guide sleeve from falling off.

The support column, ejector plate, and ejector fixing plate are important components of the mold ejection system, responsible for ejecting the molded product from the core when the mold is opened. The support column, also known as the support head, is installed between the movable mold base plate and the movable mold plate. It is used to withstand the injection pressure transmitted by the movable mold plate and prevent the movable mold plate from deforming under the action of high pressure. The ejector plate and the ejector fixing plate are connected together by ejectors, ejector plate guides, etc. One end of the ejector is fixed to the ejector fixing plate, and the other end passes through the movable mold plate and the core. When the ejector rod of the injection molding machine pushes the ejector plate, the ejector ejects the product. A reset spring is usually installed between the ejector plate and the movable mold base plate to reset the ejector after the ejection action is completed, preparing for the next injection molding. The structural design of these components needs to be optimized according to the shape of the product and the ejection requirements to ensure that the ejection force is evenly distributed and to avoid defects such as whitening and deformation of the product.