Flow balance in injection molding gating systems

Flow balance in the injection molding gating system is a key factor in ensuring consistent quality across multiple cavities in a multi-cavity mold. It requires the melt to fill each cavity in the same state and at the same time, avoiding dimensional deviations and uneven mechanical properties in the product due to filling variations. Achieving flow balance requires comprehensive consideration of multiple aspects, including gating system design, process parameter optimization, and mold structure improvements.

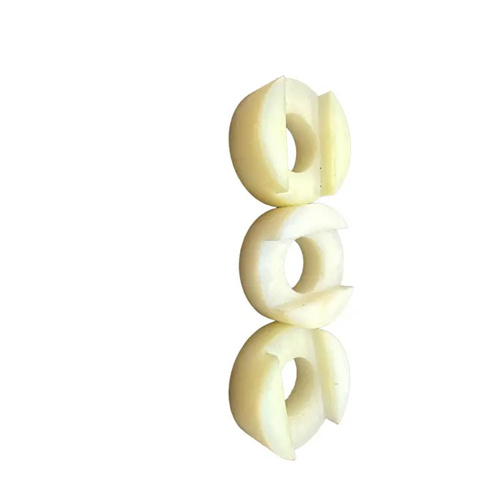

The geometric design of the pouring system is the basis for achieving flow balance. In multi-cavity molds, the size and layout of the main channel, branch channel and gate directly affect the flow path and flow resistance of the melt. In order to ensure the filling balance of each cavity, a symmetrical layout is usually adopted, that is, the cavities are symmetrically distributed around the main channel so that the flow path length of the melt from the main channel to each cavity is equal. At the same time, the cross-sectional shape and size of the branch channel should be consistent. For circular branch channels, their diameter should be calculated according to the flow characteristics of the melt to ensure that the flow resistance of the melt in each branch channel is the same. In addition, the size and type of the gate must also be unified. The same gate size can ensure that the flow rate and speed of the melt entering each cavity are consistent, avoiding filling imbalance due to gate differences.

The flow characteristics of the melt in the casting system are important factors affecting flow balance. Different plastics have different melt viscosities, fluidity, and sensitivity to temperature and shear rate. These characteristics will directly affect the flow behavior of the melt in the casting system. For low-viscosity, high-fluidity plastics, such as polyethylene (PE) and polypropylene (PP), the flow resistance of the melt in the runner is small, and flow balance is easy to achieve, but attention should be paid to controlling the injection speed to avoid uneven filling due to turbulence. For high-viscosity, low-fluidity plastics, such as polycarbonate (PC) and polyoxymethylene (POM), the flow resistance of the melt in the runner is large, and it is easy to cause filling imbalance due to slight differences in path length. Therefore, more precise casting system design and process parameter control are required.

Optimization of injection molding process parameters plays a key role in achieving flow balance. Injection speed is an important parameter that affects melt flow. An injection speed that is too fast will cause turbulence and eddy currents in the melt in the casting system, destroying the flow balance; while an injection speed that is too slow will cause the melt to cool too quickly during the flow process, increasing flow resistance and also affecting filling consistency. Therefore, it is necessary to set an appropriate injection speed according to the characteristics of the plastic and the structure of the casting system. Usually, a segmented speed regulation method is adopted. A lower speed is used in the early stage of melt filling to avoid turbulence, and the speed is appropriately increased in the later stage of filling to ensure that all cavities are filled at the same time. In addition, the melt temperature and mold temperature also need to be reasonably controlled. Stable temperature can ensure the consistency of melt viscosity and reduce flow imbalance caused by viscosity fluctuations.

The uniformity of the mold’s temperature distribution has a significant impact on the flow balance of the pouring system. If there are differences in the temperature of each mold cavity, the melt will have different cooling rates and flow resistances in different cavities, thereby disrupting the filling balance. For example, the temperature of the cavity close to the mold’s cooling water channel is lower, the melt cools faster therein, the flow resistance increases, and the filling time is prolonged; while the temperature of the cavity far from the cooling water channel is higher, the melt has better fluidity, and the filling time is shortened, resulting in inconsistent filling of each cavity. Therefore, in mold design, the cooling water channel should be arranged reasonably to ensure uniform temperature distribution of each cavity. At the same time, a temperature control system should be used to monitor and adjust the mold temperature in real time to ensure temperature stability.

Balancing the pressure loss of the pouring system is the core of achieving flow balance. The melt will experience pressure loss as it flows through the main channel, branch runners, and gates. If there are differences in pressure loss between cavities, the melt will enter each cavity at different pressures, affecting the filling speed and volume. To reduce the difference in pressure loss, the length and cross-sectional dimensions of the branch runners should be accurately calculated based on the flow path. For molds with an asymmetric layout, the pressure loss can be compensated by adjusting the size of the branch runners. For example, the cross-sectional dimensions of a branch runner with a longer flow path can be appropriately increased to reduce flow resistance. At the same time, the pressure loss of the gates also needs to be balanced. By adjusting the size and shape of the gates, the pressure loss of the melt passing through each gate can be made the same, ensuring consistent filling pressure for each cavity. In addition, the injection pressure and holding pressure settings of the injection molding machine must also match the pressure loss characteristics of the pouring system to ensure that the melt has sufficient pressure to maintain flow balance during the filling and holding stages.