Several Problems on Air Traps and Their Improvement Measures

Air entrapment is a common defect in injection molding caused by the inability to expel gas from the mold cavity in a timely manner. It manifests as scorching on the surface of the plastic part, bubbles, missing material, and noticeable weld marks. This not only affects the product’s appearance but can also reduce mechanical properties. Air entrapment often occurs in areas where the melt is last filled, such as cavity corners, areas with sudden changes in wall thickness, and the base of ribs. For example, the corners of a mobile phone casing exhibited scorching marks due to trapped air, causing the pass rate to drop from 95% to 82%. Air entrapment is essentially caused by the melt filling rate exceeding the gas discharge rate or by improper exhaust duct design. It involves multiple factors, including mold structure, process parameters, and plastic properties. Solving the problem of air entrapment requires a systematic analysis of the gas sources (including cavity air, raw material volatiles, and release agent volatiles). Targeted measures such as exhaust optimization and process adjustments are then implemented to control the gas content below 0.1% to ensure consistent part quality.

The main causes of trapped gas include inadequate mold venting, an unreasonable melt filling path, and improper process parameter settings. Insufficient mold venting is the most common cause. If the vent groove is too shallow (less than 0.01mm) or insufficient in length, gas cannot be discharged in a timely manner. For example, the vent groove depth for small plastic parts requires 0.01-0.02mm, while that for large parts requires 0.02-0.03mm. Too shallow will not vent, while too deep will cause flash. An unreasonable melt filling path can cause “trapped gas” phenomenon. For example, when melt in a complex cavity converges from multiple directions, gas can be trapped in the center, forming weld marks and bubbles. A car dashboard, filled with four gates, has significant trapped gas in the center. In terms of process parameters, if the injection speed is too fast, the melt front will quickly close the exhaust channel. For example, when the injection speed is increased from 50mm/s to 80mm/s, the gas entrapment defect rate may increase by 3 times; if the melt temperature is too high, it will cause excessive volatilization of the raw materials and increase the amount of gas. For example, when the PC temperature exceeds 320℃, the volatile matter increases by more than 50%, exacerbating the gas entrapment.

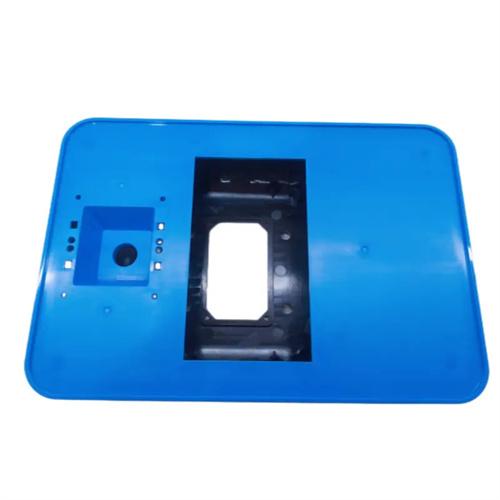

Optimizing the mold’s exhaust system is a key measure to address trapped air. An efficient exhaust solution must be designed based on the part’s structure and filling path. Venting grooves must be installed in areas where the melt is last filled, such as the cavity edge, the bottom of the rib, and the side of the boss. These grooves are typically 5-10mm wide and extend to the outside of the mold to ensure that gas is directly discharged from the mold. For deep or complex cavities, exhaust inserts (such as powder metallurgy breathable steel) can be used. Their microporous structure (pore size 5-20μm) allows for exhaust without leaking the melt, making them suitable for areas where traditional venting grooves are difficult to install. For example, the deep cavity of a laptop computer case can reduce the air entrapment defect rate from 15% to 3% with the use of breathable steel inserts. The clearance of the parting surface is also a critical exhaust channel and must be controlled at 0.01-0.02mm. For large molds, a network of exhaust grooves can be added to the parting surface to cover the entire cavity edge. In addition, the clearance between the ejector pin and the ejector pin hole (0.01-0.03mm) can also assist in exhaust. The exhaust efficiency can be improved by increasing the number of ejector pins. For example, more ejector pins with a diameter of 3-5mm can be installed in areas with severe air entrapment to enhance local exhaust.

Adjusting process parameters can effectively reduce the likelihood of trapped air. By optimizing injection, holding pressure, and temperature parameters, a balance between filling and venting speeds is achieved. Using staged injection speed control is crucial. Initially, a low speed (20-30 mm/s) ensures smooth melt filling and prevents rapid closure of venting channels. When the melt fills 80%-90% of the cavity volume, the speed is reduced again (10-20 mm/s) to allow time for gas to escape. For example, a two-stage “high-speed-low-speed” injection process for a box-shaped part reduced scorching defects caused by trapped air by 70%. The melt temperature should be controlled within the lower-middle range of the plastic’s processing temperature range to minimize volatile emissions. For example, the optimal temperature for ABS is 220-240°C; temperatures exceeding 250°C significantly increase volatile gas emissions. The holding pressure and time should be appropriately reduced. Excessive holding pressure compresses residual gas in the cavity, leading to localized excessive pressure and scorching. The holding pressure should be 60%-70% of the injection pressure, and the holding time should be extended by 1-2 seconds after the cavity is fully filled. In addition, increasing the mold temperature by 10-20°C can reduce the melt viscosity, extend the filling time, and indirectly improve degassing. For example, when the mold temperature of PP plastic parts is increased from 40°C to 60°C, the melt flows more smoothly and the air trapped area is significantly reduced.

Raw material pretreatment and auxiliary measures also play a positive role in reducing trapped air, especially for highly hygroscopic or volatile plastics. Raw material drying is fundamental. Hygroscopic plastics (such as PA and PC) must be thoroughly dried before processing. PA66 should be dried at 80-100°C for 4-6 hours, and PC at 120-140°C for 6-8 hours to reduce the moisture content to below 0.05%, thereby reducing water vapor generation during the molding process. Mold release agents should be used in moderation; excessive amounts can evaporate and produce gas at high temperatures. A spray-type release agent is recommended, with a dosage of 0.5-1mL per mold, and high-temperature resistant (>200°C) should be selected. For raw materials with excessive gas content, a venting device can be installed on the barrel, or vacuum injection molding can be used to extract gas from the melt through negative pressure. For example, in the production of precision optical plastic parts, vacuum injection molding can reduce bubble defects caused by trapped air by over 90%. In addition, mold cavities and runners are regularly cleaned to prevent the accumulation of decomposition products and the generation of gases. A thorough cleaning is performed every 1,000 molds to ensure unobstructed exhaust ducts. Through comprehensive optimization of molds, processes, and raw materials, the gas entrapment defect rate can be controlled below 1%, significantly improving part quality and production efficiency.