Shape design of injection molding parting surface

The shape design of the injection molding parting surface is a core part of mold structure design, which directly affects the demolding effect, appearance quality and mold processing difficulty of the plastic part. The parting surface is the contact surface between the movable mold and the fixed mold. Its shape must match the contour of the plastic part to ensure that the complete shape of the plastic part is formed when the cavity is closed, and at the same time facilitate the smooth demolding of the plastic part and the solidified material. Common parting surface shapes include planes, inclined surfaces, stepped surfaces, curved surfaces and irregular curved surfaces. Different shapes are suitable for different plastic part structures. For example, plane parting surfaces are suitable for flat plastic parts, and curved parting surfaces are suitable for spherical or arc-shaped plastic parts. The design of the parting surface must comprehensively consider the geometric shape, dimensional accuracy, appearance requirements and mold manufacturing process of the plastic part. Reasonable shape design can simplify the mold structure, reduce costs and improve production efficiency. Otherwise, it may cause problems such as flash, deformation or demolding difficulties of the plastic part.

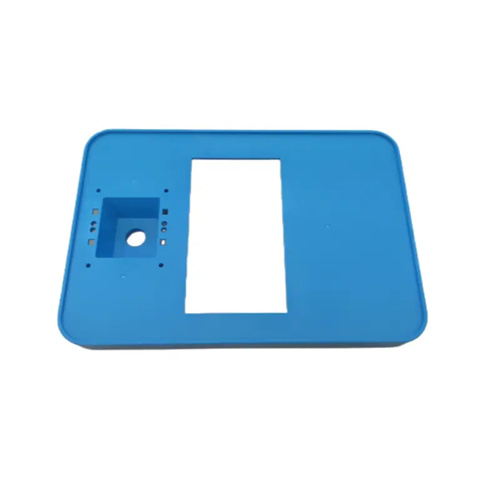

A flat parting surface is the most basic and widely used parting method, suitable for simple flat or box-shaped parts. Its characteristics include a regular shape and ease of machining, typically achieved with a milling or grinding machine. Its flatness tolerance can be controlled to within 0.01mm/m, ensuring a tight fit during mold closing and reducing the risk of flash. A flat parting surface is typically located at the part’s largest contour. For example, the parting surface of a square box lid is located on the flat surface of the box’s opening, facilitating demolding while ensuring a smooth edge. For parts with a low height (less than 50mm), a flat parting surface simplifies the mold structure, eliminating the need for complex guide mechanisms and reducing mold costs. However, a flat parting surface is not suitable for parts with complex curves or deep cavities. For example, using a flat parting surface for a spherical part would result in noticeable flash at the parting surface and make demolding difficult. In these cases, a curved parting surface is required.

Beveled parting surfaces are suitable for parts with inclined structures or large draft angles. Designing a parting surface parallel to the part’s inclined surface ensures tight cavity closure and smooth part demolding. The angle of the beveled parting surface must match the part’s draft angle, typically ranging from 5° to 30 °. If the angle is too large (>30°), a positioning mechanism (such as a tapered locating pin) is required to prevent mold misalignment during mold closing. For example, a part with a 15° beveled parting surface using the same angle reduces the flash rate from 8% to 1% compared to a flat parting surface, and also allows for smoother demolding. Beveled parting surfaces should be milled using a milling machine or machining center, with a surface roughness of Ra0.8μm or less. Wear-resistant blocks (such as Cr12) should be placed between the mating surfaces to prevent wear from long-term use. For plastic parts with bidirectional inclination, a combined inclined parting surface can be used, that is, the parting surface is composed of two inclined surfaces with different angles, which are respectively adapted to the different inclined parts of the plastic part.

Stepped parting surfaces are suitable for plastic parts with significant height steps or dimensional variations. These surfaces are formed by multiple parallel planes to ensure a tight seal at each step. For example, for a housing part with a boss, the parting surface should be stepped as the boss height changes, ensuring a fully closed cavity around the boss and preventing flash. When designing a stepped parting surface, attention should be paid to the parallelism of each step, with an error of ≤0.02mm/m. Otherwise, additional torque will be generated during mold closing, leading to mold deformation. The transitions between steps should be rounded (radius ≥3mm) to avoid stress concentration. During machining, each step surface is processed step by step using a CNC milling machine to ensure dimensional accuracy, followed by overall grinding to ensure flatness. While stepped parting surfaces can accommodate complex height variations, they increase mold processing difficulty and cost. They are suitable for medium-volume production and above. For small-batch production, flat parting surfaces can be used to reduce mold costs by adding a trimming step.

Curved and irregular parting surfaces are suitable for plastic parts with complex curved contours, such as automobile bumpers and appliance housings. Their shape must perfectly conform to the exterior or interior surface of the part to ensure cavity integrity and the quality of the part’s appearance. Curved parting surfaces must be precisely designed using 3D modeling software (such as UG and Pro/E), with a fit tolerance of ≤0.05mm to the part surface to avoid flash caused by excessive clearance. Milling of these surfaces is performed using a five-axis machining center, achieving a surface roughness of Ra 0.4μm or less. EDM and polishing are performed as necessary to ensure surface smoothness. Irregular parting surfaces are used for parts with unusual shapes, such as those with multiple protrusions, depressions, or lateral holes. Parting surfaces must avoid the part’s exterior and functional areas. For example, they can be located inside or in a hidden area to minimize appearance degradation. Molds with curved and irregular parting surfaces require high-precision guide mechanisms (e.g., guide pin and sleeve clearances ≤ 0.01mm) and positioning mechanisms (e.g., taper positioning) to ensure precise mold closing. While these parting surfaces are complex and costly to manufacture, they can significantly improve the quality and production efficiency of complex plastic parts, making them a common choice for high-end mold design.