In the ever – evolving construction industry, POM injection molding has emerged as a valuable technology, enabling us to produce components that combine exceptional mechanical strength, durability, and precision. By leveraging the unique properties of polyoxymethylene (POM) and the capabilities of injection molding processes, we can create parts that meet the diverse and demanding requirements of modern construction projects, from enhancing structural integrity to improving functionality. POM injection molding is playing an increasingly significant role in driving innovation and improving the overall quality of construction.

1. The Material Advantages of POM Injection Molding for Construction

When we undertake construction projects, the selection of POM for injection molding is driven by its outstanding material attributes. POM offers high mechanical strength and rigidity, making it an ideal choice for components that need to withstand heavy loads and mechanical stress. Its excellent tensile strength allows POM – injection – molded parts to resist deformation under pressure, ensuring the stability and reliability of construction structures. For example, in load – bearing applications, POM – molded connectors and brackets can provide strong support, enhancing the structural integrity of buildings.

One of the key properties of POM is its low coefficient of friction. This characteristic is particularly beneficial for construction components that require smooth movement, such as sliding doors, windows, and adjustable structures. POM – injection – molded tracks and rollers enable these elements to operate smoothly with minimal friction, reducing wear and tear and extending their lifespan. Additionally, POM has good chemical resistance, which means it can withstand exposure to common construction materials, cleaning agents, and environmental factors without degrading. This makes it suitable for use in various construction environments, from indoor to outdoor applications.

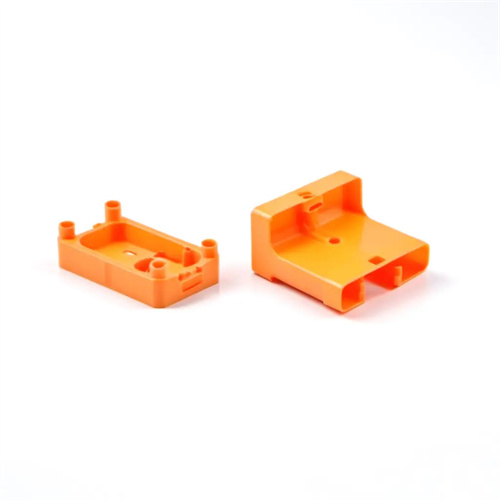

2. POM Injection Molding in Construction Component Manufacturing

POM injection molding is widely applied in the production of various construction components. In the field of architectural hardware, POM – injection – molded parts are commonly used for handles, hinges, and locks. The high strength and durability of POM ensure that these components can withstand frequent use and harsh environmental conditions. POM – molded door handles, for instance, not only provide a comfortable grip but also maintain their shape and functionality over time. The precision of injection molding allows for the creation of intricate designs, enabling us to produce hardware that combines both aesthetics and practicality.

For building services and infrastructure, POM – injection – molded components play a crucial role. In plumbing systems, POM – molded pipes and fittings offer excellent chemical resistance and durability, ensuring long – term performance and preventing leaks. Their smooth inner surfaces reduce friction, promoting efficient water flow. In electrical installations, POM – injection – molded cable conduits and insulation parts provide reliable protection for electrical cables, withstanding mechanical stress and electrical insulation requirements.

3. Precision and Durability in POM Injection Molding for Construction

Precision is at the heart of our POM injection molding processes for construction. Advanced injection molding machines, equipped with sophisticated computer – controlled systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing small and complex construction components, like the tiny fasteners in prefabricated building modules or the detailed parts of architectural models, we can fine – tune the injection process to achieve extremely tight tolerances. The dimensions of POM – injection – molded parts can be produced with an accuracy of ±0.02mm, ensuring a perfect fit and seamless integration within the construction structure.

Durability is equally important in construction applications. POM – injection – molded components are designed to withstand the rigors of construction environments. Their resistance to wear, impact, and environmental factors ensures that they maintain their performance over the long term. Whether it’s a POM – molded structural connector exposed to the elements in an outdoor construction project or an interior component subject to daily use, the durability of POM helps reduce maintenance costs and extends the lifespan of the construction project.

4. Cost – Efficiency of POM Injection Molding in Construction Projects

Cost – efficiency is a critical consideration in construction, and POM injection molding offers significant advantages in this regard. Although the initial investment in mold development for POM injection molding can be substantial, especially for complex designs, the long – term benefits far outweigh the costs. The mass – production capabilities of injection molding enable us to produce POM parts at a relatively low cost per unit. When manufacturing large quantities of POM – injection – molded plumbing fittings or electrical conduit components for a construction project, the economies of scale reduce the overall production cost significantly.

The automated nature of the POM injection molding process also helps in reducing labor costs. With computer – controlled machines handling most of the production tasks, we require fewer operators, minimizing the risk of human – error – related defects. Additionally, the durability and long service life of POM – molded components mean less frequent replacement and maintenance, resulting in further cost savings over the life cycle of the construction project. By optimizing the design for manufacturability and streamlining production processes, we can offer cost – effective construction solutions without compromising on quality.

5. Future Prospects of POM Injection Molding in the Construction Industry

As we look to the future, we are excited about the potential of POM injection molding in the construction industry. With the growing emphasis on sustainable construction, we anticipate the development of more eco – friendly POM – based materials. Researchers may focus on creating bio – based POM or enhancing the recyclability of POM – molded parts, reducing the environmental impact of construction projects.

Advancements in technology will also open up new possibilities. We expect to see more integration of smart features into construction components, and POM injection molding could play a role in housing sensors, monitoring devices, and other intelligent elements. Additionally, as construction techniques evolve towards more modular and prefabricated methods, POM – injection – molded components will become even more important due to their precision and compatibility with modern construction processes. These future developments will undoubtedly expand the applications and influence of POM injection molding, driving the continued innovation and progress of the construction industry.