In the realm of household appliance manufacturing, PET (Polyethylene Terephthalate) injection molding has emerged as a transformative technology, enabling us to craft components and products that combine functionality, durability, and aesthetic appeal. This versatile manufacturing process, with its unique combination of PET material properties and precise molding techniques, offers us a plethora of benefits. From enhancing the performance of appliances to reducing production costs, PET injection molding plays an indispensable role in meeting the diverse needs of consumers and driving innovation in our industry.

1. The Material Merits of PET Injection Molding for Household Appliances

When we opt for PET injection molding in the production of household appliances, we leverage the exceptional properties of PET. Its high mechanical strength is crucial for ensuring the durability of appliance components. For instance, in washing machines, PET – molded detergent drawers can withstand the constant opening and closing, as well as the weight of detergents and fabric softeners, without deforming or breaking over time. Rigorous testing has shown that these drawers can endure tens of thousands of cycles of use, maintaining their structural integrity throughout.

PET also boasts excellent chemical resistance, which is vital for appliances that come into contact with various cleaning agents, solvents, and food substances. In dishwashers, PET – molded racks resist corrosion from harsh detergents, ensuring a long service life. Similarly, in refrigerators, PET components used in food storage compartments are impervious to the acids and enzymes present in food, preventing any chemical reactions that could affect the quality of stored items or the performance of the appliance.

2. Precision and Quality Assurance in PET Injection Molding Processes for Household Appliances

Precision is the cornerstone of our PET injection molding operations for household appliances. Our advanced injection molding machines, equipped with sophisticated computer – controlled systems, allow us to precisely regulate parameters such as injection pressure, temperature, and cooling time. When manufacturing intricate components like the control knobs for ovens, we can fine – tune the injection pressure to ensure that the molten PET fills the mold cavities with utmost accuracy. This level of control enables us to achieve tight tolerances; for example, the dimensions of PET – molded air vents in air conditioners can be produced with an accuracy of ±0.03mm, ensuring a perfect fit and optimal air circulation.

Quality assurance is an integral part of our production process. We implement a series of strict inspection procedures, from the initial mold design stage to the final product assembly. Using advanced non – destructive testing methods, such as X – ray imaging and ultrasonic testing, we can detect any internal defects in the PET – molded components, like voids or inclusions, that might compromise their performance. Additionally, we conduct rigorous functional tests to ensure that each component meets our high – quality standards before it is incorporated into the appliance. This comprehensive quality control system helps us minimize product failures and maintain the trust of our customers.

3. Design Versatility Enabled by PET Injection Molding in Household Appliances

PET injection molding empowers us to unleash our creativity in the design of household appliances. We can create components with a wide range of shapes, sizes, and textures to meet the aesthetic and functional requirements of different appliances. For example, in modern kitchen hoods, we can mold PET into sleek, curved shapes that not only enhance the visual appeal but also optimize the airflow for efficient ventilation. The ability to incorporate various finishes, such as matte, glossy, or textured surfaces, allows us to customize the appearance of our appliances to match different kitchen or home decor styles.

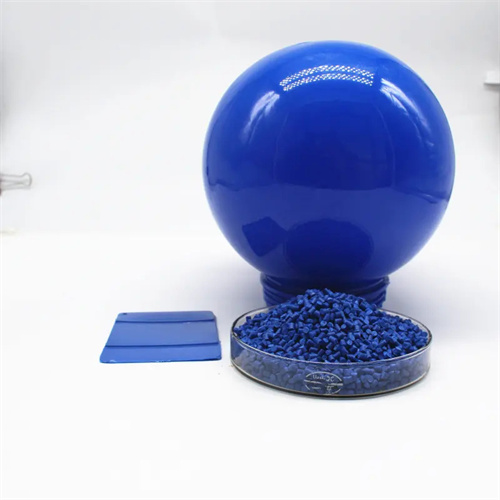

Customization is a significant advantage. We can choose from a vast array of colors by adding color masterbatches during the PET injection molding process, enabling us to create appliances that blend seamlessly with the overall interior design. Additionally, we can integrate functional features directly into the PET – molded components. For instance, in vacuum cleaners, we can design PET – molded handles with ergonomic grips, making the appliance more comfortable to use. We can also incorporate snap – fit mechanisms, slots for accessories, or mounting points, which not only improve the usability of the appliance but also simplify the assembly process.

4. Cost – Efficiency of PET Injection Molding in Household Appliance Production

Cost – efficiency is a key consideration in our household appliance production, and PET injection molding offers substantial advantages in this regard. Although the initial investment in mold development, especially for complex designs, can be significant, the long – term benefits far outweigh the costs. The mass – production capabilities of PET injection molding allow us to produce components at a relatively low cost per unit. When manufacturing 100,000 PET – molded refrigerator door bins in a single batch, the cost per piece can be reduced to as low as $0.50, making it a cost – effective option compared to other manufacturing methods.

The automated nature of the injection molding process also contributes to cost savings. With computer – controlled machines handling most of the production tasks, we require fewer operators, significantly reducing labor costs. Moreover, the high precision and consistency of the process minimize the occurrence of defective products. In our production facilities, the defect rate of PET – molded appliance components is typically less than 1%, which reduces the expenses associated with rework, scrap, and product recalls. By optimizing the design for manufacturability and streamlining our production processes, we can offer high – quality household appliances at competitive prices.

5. Future Horizons of PET Injection Molding in the Household Appliance Industry

As we look towards the future, we are excited about the prospects of PET injection molding in the household appliance industry. With the increasing demand for smart and energy – efficient appliances, we anticipate further advancements in PET material properties. Researchers are exploring ways to enhance the thermal conductivity of PET, which would enable better heat dissipation in appliances like microwave ovens and clothes dryers, leading to more compact and energy – efficient designs.

We also expect to see more integration of smart features into PET – molded components. By embedding sensors, microcontrollers, and wireless communication modules directly into PET – molded parts, we can create appliances that are capable of self – diagnosis, remote control, and energy management. Additionally, as sustainability becomes an even more pressing concern, we are committed to developing more eco – friendly PET formulations, such as bio – based PET. This would not only reduce the environmental impact of our appliances but also meet the growing consumer demand for green products. These future developments will undoubtedly expand the capabilities of PET injection molding and drive the household appliance industry towards a more innovative and sustainable future.