As manufacturers deeply rooted in the toy industry, we have long recognized ABS injection molding as a cornerstone technology in our production processes. This versatile manufacturing method has revolutionized the way we create toys, enabling us to produce high-quality, safe, and engaging products that capture the imagination of children worldwide. From intricate action figures to colorful building blocks, ABS injection molding offers a plethora of advantages, combining precision, durability, and aesthetic appeal to meet the diverse demands of the market.

1. The Fundamental Process of ABS Injection Molding in Toy Production

The journey of ABS injection molding in toy manufacturing commences with the careful selection of ABS pellets. These pellets, known for their excellent mechanical properties and safety features, are fed into the hopper of an injection molding machine. From there, they are transported to a heated barrel, where the temperature is meticulously regulated, typically ranging from 200°C to 260°C. This heat, combined with the mechanical action of a rotating screw, gradually melts the ABS material into a viscous liquid.

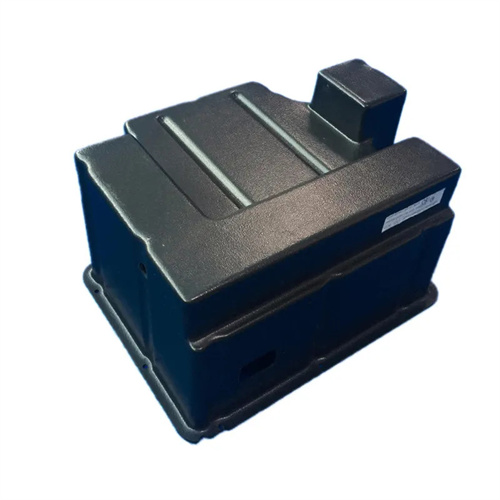

Once in a molten state, the ABS is injected under high pressure, usually between 70 and 150 megapascals, into a precisely designed mold cavity. The mold, often crafted from high-grade steel or aluminum, is customized according to the specific requirements of the toy. For example, when creating a detailed toy car body, the mold will include features such as doors that can open, headlights, and intricate body lines. After injection, a cooling system within the mold rapidly cools the ABS, causing it to solidify and take on the exact shape of the mold. Once fully cooled, the mold opens, and the finished ABS toy component is ejected, ready for further processing, such as painting, assembly, or packaging.

2. Design Flexibility Enabled by ABS Injection Molding

One of the most remarkable advantages of ABS injection molding in the toy industry is its unparalleled design flexibility. It allows us to bring even the most imaginative and complex toy designs to life. Whether it’s a fantastical creature with multiple limbs and textures or a detailed miniature replica of a real-world object, ABS injection molding can handle it with ease.

For instance, in the production of action figures, we can create highly detailed facial features, realistic clothing folds, and articulated joints, all in a single molding process. This level of detail not only enhances the visual appeal of the toys but also makes them more engaging for children. Additionally, we can customize the color, size, and shape of ABS toy components to meet the specific preferences of different age groups and market segments. By adding color masterbatches during the molding process, we can create a wide range of vibrant and eye-catching colors, from bright primary hues for younger children to more subdued tones for collectible toys.

3. Safety and Durability Assurance by ABS Injection Molding

Safety and durability are of utmost importance in the toy industry, and ABS injection molding plays a crucial role in ensuring both. ABS is a non-toxic material that meets strict safety standards, making it ideal for toys that children will handle and play with. It is resistant to breakage and cracking, even under rough play, which helps prevent the formation of sharp edges or small parts that could pose a choking hazard.

Our rigorous testing procedures have shown that ABS-molded toys can withstand significant impacts and stresses without damage. For example, toy building blocks made from ABS can be stacked, knocked over, and rebuilt countless times without losing their shape or structural integrity. Moreover, ABS has good chemical resistance, which means it can resist the effects of common household cleaners and substances that children might expose the toys to, ensuring the longevity of the products.

4. Cost – effectiveness of ABS Injection Molding in Toy Manufacturing

In the highly competitive toy market, cost – effectiveness is key to our business success, and ABS injection molding offers significant cost – saving opportunities. While the initial investment in mold creation for ABS injection molding can be substantial, especially for complex toy designs, the long-term benefits far outweigh the upfront costs.

Once the mold is fabricated, the injection molding process can produce large quantities of identical toy components with minimal material waste. For example, when manufacturing plastic toy soldiers, a single mold can produce thousands of units per day. The economies of scale achieved through high-volume production reduce the per-unit cost of the toys significantly. Additionally, the ability to integrate multiple functions into a single ABS-molded part, such as wheels on a toy vehicle or handles on a playset, reduces the need for additional assembly steps and components, further saving on labor and production costs.

5. Future Prospects of ABS Injection Molding in the Toy Industry

Looking ahead, we are excited about the future prospects of ABS injection molding in the toy industry. As technology continues to advance, we anticipate several exciting developments. Researchers are working on developing new formulations of ABS with enhanced properties, such as improved flexibility and better heat resistance. These advancements will open up new possibilities for toy design, allowing us to create more dynamic and interactive toys.

In addition, the integration of advanced manufacturing technologies, such as 3D printing and automation, with ABS injection molding is on the horizon. 3D printing can be used for rapid prototyping, enabling us to quickly test and refine new toy designs before mass production. Automation in the injection molding process will increase production efficiency, reduce human error, and improve the consistency of product quality. Furthermore, with the growing focus on sustainability, we expect to see an increased use of recycled ABS materials in toy production, reducing our environmental impact while still maintaining the high standards of safety and quality that our customers expect.