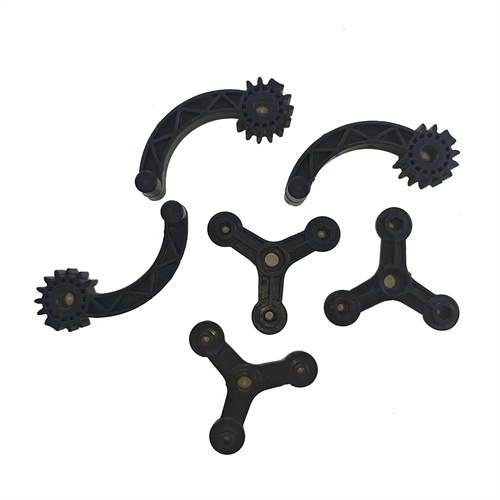

POM Injection Molding

The POM injection molding technology we use relies on the excellent performance of polyoxymethylene (POM) material to show significant technical advantages. POM material has extremely high mechanical strength and rigidity, and the products made are wear-resistant, fatigue-resistant, and able to withstand long-term high-load work, which makes it excellent in the manufacture of mechanical transmission components. Its excellent self-lubricating properties reduce friction without the need for additional lubricants, effectively reducing energy consumption and extending service life. POM is chemically stable, resistant to acid and alkali corrosion, and can maintain stable performance in harsh chemical environments. In addition, POM injection molded products have high dimensional accuracy, low shrinkage, and good repeatability, making them suitable for manufacturing precision parts. In addition, POM material has a short molding cycle and high production efficiency, which can meet the needs of mass production, which provides strong support for us to reduce production costs and improve market competitiveness.

POM Injection Molding Material Selection: A wide range of types that are precisely adapted to your needs

In the material selection stage, we will accurately select the appropriate POM material according to different product application scenarios and performance requirements. Acetal homopolymer (POM-H) has higher mechanical strength and rigidity, as well as excellent creep resistance, and is suitable for manufacturing precision parts that require high strength and dimensional stability, such as clock gears, automobile engine fuel pump gears, etc. Acetal copolymer (POM-C) has better thermal stability and chemical resistance while maintaining good mechanical properties, and is often used in the manufacture of bathroom faucet valve cores, automobile wiper transmission parts, etc. In addition, there are some specially modified POM materials, such as POM reinforced with glass fiber, which can further improve the strength, rigidity and dimensional stability of the material, and is suitable for the manufacture of mechanical structural parts that bear large loads; The addition of molybdenum disulfide or graphite to self-lubricating grade POM can significantly enhance the lubricating properties of the material, and is commonly used in the manufacture of components that require low friction, such as plain bearings and guide rails. We also comprehensively consider the melt flow rate, density and other parameters of the material to ensure that it has good flow and formability during the injection molding process, so as to produce high-quality products.

POM Injection Molding Production Process: Strict and standardized manufacturing process

Our POM injection molding production process follows strict operating practices. The first is the mold design and manufacturing process, according to the three-dimensional model of the product, the use of professional design software for precision design, fully considering the shrinkage, fluidity and other characteristics of POM materials, to ensure that the mold structure is reasonable and the size is accurate. Then the mold is manufactured through high-precision processing equipment, and the surface quality and dimensional accuracy of the mold are strictly controlled, providing a reliable guarantee for product molding. Then the POM raw material is pre-treated, because the POM material has low hygroscopicity but is sensitive to moisture, we will dry the raw material at a temperature of 80 – 90°C for 3 – 4 hours to remove moisture and prevent defects such as bubbles and silver wires from appearing during the molding process. Then enter the injection molding process, the dried POM raw material is fed into the barrel of the injection molding machine, heated to a molten state (the temperature is generally controlled at 190 – 220°C), quickly injected into the mold cavity under high pressure, and the product is fully filled after pressure holding, and then quickly cooled and shaped through the cooling system (the cooling time is usually 10 – 30 seconds depending on the thickness of the product). Finally, the post-processing process includes the removal of gates, burrs, necessary trimming and quality inspection of the product to ensure that each product meets the quality standards.

POM Injection Molding Surface Treatment: A variety of technologies to improve performance and aesthetics

We use a variety of surface treatment techniques to enhance the performance and appearance of POM injection molded products. For products that need to improve surface hardness and wear resistance, we will carry out electroless nickel plating or chrome plating to form a hard metal protective layer on the surface of the product, which can effectively enhance the wear resistance and corrosion resistance of the product. In order to improve the appearance and texture of the product, we can use the spraying process to spray a variety of colors and textures according to the design requirements, giving the product rich colors and unique visual effects, while improving the weather resistance and stain resistance of the product. In addition, screen printing and laser engraving technology can add text, patterns and logos to the surface of the product to meet the needs of personalized customization and enhance the brand recognition of the product. For some products with special requirements for surface roughness, we will also polish or frost the surface roughness of the product to adjust the roughness of the product surface to adapt to different use scenarios.

POM Injection Molding Dimensional Inspection: Strict and precise quality control system

In terms of dimensional inspection, we have established a strict and precise quality control system. First of all, use calipers, micrometers and other conventional measuring tools to make a preliminary measurement of the key dimensions of the product, and quickly screen out the products that obviously do not meet the requirements. For products with high precision requirements, we use a three-coordinate measuring instrument for accurate measurement, which can detect the product in a three-dimensional space in an all-round way, accurately obtain the size deviation of the product, geometric tolerance and other data, and ensure that the product size meets the design requirements. At the same time, we will also use optical inspection equipment to quickly detect and compare the appearance and size of products through image recognition technology, and find small size differences and defects in time. In addition, we regularly calibrate and maintain our measurement equipment to ensure the accuracy and reliability of our test data. Through the comprehensive use of a variety of testing methods, we strictly control the quality of products to ensure that the dimensional accuracy of each product can meet high standards.

POM Injection Molding product application: extensive and in-depth multi-field coverage

POM injection molded products are used in a wide range of applications in our lives and production. In the automotive industry, POM is widely used in the manufacture of automotive door lock systems, window regulators, wipers, fuel system parts, etc., with excellent mechanical properties and oil resistance, effectively improving the reliability and service life of automobiles. In the home appliance industry, POM is often used in the manufacture of washing machine gearboxes, refrigerator drawer slides, air conditioning fan blades, etc., with its self-lubricating and wear-resistant characteristics, reducing the noise and wear of household appliances during operation. In the field of electronic appliances, POM is used to manufacture precision components such as connectors, switches, keyboard keys, etc., and its high precision and good electrical insulation properties meet the needs of miniaturization and precision of electronic products. In addition, POM injection molding products also play an important role in medical devices, office equipment, sports equipment and other industries, such as gear transmission components in medical devices, printer transmission gears in office equipment, bearings and pulleys in sports equipment, etc., and their excellent properties make them indispensable engineering plastic materials in many industries.